Wastech takes out garbage with SolidWorks

Leading waste disposal solution supplier, Wastech Engineering, has dramatically improved its design and modelling processes by upgrading its CAD software to SolidWorks from Australian reseller, Solidtec Solutions.

Leading waste disposal solution supplier, Wastech Engineering, has dramatically improved its design and modelling processes by upgrading its CAD software to SolidWorks from Australian reseller, Solidtec Solutions.

A leading supplier of waste management products and consulting solutions, Wastech Engineering designs and manufactures garbage and recycling chutes, compactors, bin lifters, garbage trucks and waste transfer stations.

The Challenge

Since every client’s waste management requirements are different, Wastech incorporates a high level of customisation in every design, using 3D CAD software to create and test its models.

Wastech Mechanical Design Engineer, Andrew Puclin, said the company’s previous 3D CAD solution was extremely slow and cumbersome to use, requiring complex processes to revise design iterations.

“We are a design-led company, so the CAD software we use has a huge impact on our ability to deliver results to clients in a timely manner,” said Mr Puclin. “Because of the complexity of the previous software, we could only use it for high-end design and presenting new concepts to clients in a 3D format.”

The Solution

Mr Puclin had previously used SolidWorks at another company and, knowing that it would significantly enhance Wastech’s design capabilities, he persuaded management to make the switch in mid-2009.

Wastech purchased three licences of SolidWorks (one Premium and two Standard) for its design engineers. Not only does the software run more efficiently on the same hardware platform, but SolidWorks is more feature-rich and intuitive, guiding the users through the design process and enabling them to complete tasks much more quickly.

“SolidWorks delivers greater functionality and ease of use, allowing us to create 3D models in half the time we used to need,” said Puclin. “The Standard licences offer all the functionality we need to accomplish our design tasks, while the Premium version also includes advanced capabilities for simulations, stress analysis, rendering, and more,” he explained.

“Particularly useful are features like the limit mate, which allows us to suppress relationships between components to quickly resolve design challenges and test the new models in a range of scenarios.”

With a strong emphasis on quality and performance, the Wastech team uses the Simulation (Xpress) tool within SolidWorks to measure stresses in beams and structural members to ensure the design components will be durable enough to withstand real-world conditions.

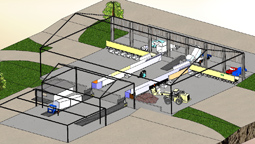

“One of our biggest projects so far was a waste transfer station for CityWide in Melbourne which gives garbage trucks a local facility to dump their waste rather than having to take it all the way to the tip. Over a four month period, we used SolidWorks to design everything from the buildings and compactors through to the front-lift trucks that deliver the garbage.”

Wastech Engineering chose to purchase SolidWorks from Solidtec Solutions, a value added reseller with offices throughout Australia and New Zealand. With a clear focus on the mechanical 3D CAD market, Solidtec maintains an experienced team of design and manufacturing industry professionals who are passionate about delivering the highest quality of technical expertise to their customer base.

“The Solidtec team has been really responsive and we’ve been very happy with the level of service they’ve provided,” said Mr Puclin. “When we had a problem downloading a very large update file because of internal server problems, they came out with the file on a disk. They really go out of their way to help us.”

Benefits

SolidWorks has enabled Wastech’s design team to dramatically increase its output and quality.

“An experienced CAD user can be up to speed with SolidWorks within a week and then they produce at least double what they used to,” said Mr Puclin. “Design cycles are much faster and people actually enjoy using SolidWorks, so we’re getting maximum value from our investment.”

SolidWork’s advanced testing and simulation capabilities also improve productivity and efficiency.

“Knowing that we are on track early on in the design process allows us to make the most of our design effort. Quality is also enhanced, thanks to the improved ease of use and the software’s intelligent design, which anticipates what you’re trying to do and leads you through it.”

Since introducing SolidWorks, Wastech has expanded its use of 3D CAD technology and now uses SolidWorks for every new design project. This has the benefit of not only reducing the time to market for new designs, but also helps to improve the sales process.

“It’s much easier to sell a concept where the customer can see a 3D model and even do a virtual walk-through than it is to sell a two dimensional drawing of a project design. We’ve had great feedback from our customers to the designs we’ve created in SolidWorks and they love the speed with which we can incorporate their changes to create new iterations.”

An added benefit is SolidWorks” ability to automatically generate a Bill of Materials, which can be exported straight into Excel. “We can now give a client an exploded view of their design with a list of all the spare parts and serviceable components, which is something we couldn’t do before. This also means a significant saving in time for our admin people, who previously would have had to compile such the bill of materials manually,” Mr Puclin explained.

Wastech is now planning to purchase its fourth SolidWorks licence as it further expands its reliance on this powerful solution.

“SolidWorks has become a valuable asset that enables us to focus on our core business of designing and building innovative and efficient waste management solutions. We have every intention of continuing to use this software for many years to come.”

nextSTEP

Contact; Shane Preston www.solidtech.com.au