Is the food and beverage sector suitable for Competitive Manufacturing?

Can the concepts of Competitive Manufacturing apply to the Food and Beverage Sector? Many of the tools and techniques used have been developed in the automotive and electronics industries, and we are often asked how they can work in a seasonal industry situation. These industries are typically “Manufacture and Assemble” rather than the “Disassemble” or “Process” that you find in the food and beverage sector.

Can the concepts of Competitive Manufacturing apply to the Food and Beverage Sector? Many of the tools and techniques used have been developed in the automotive and electronics industries, and we are often asked how they can work in a seasonal industry situation. These industries are typically “Manufacture and Assemble” rather than the “Disassemble” or “Process” that you find in the food and beverage sector.

In this article we’ll explore some of the differences and how Competitive Manufacturing Qualifications can be used to accelerate change and productivity gains in these sectors.

The food and beverage sector can be very seasonal, and many lean practitioners are used to constant demand industries, as such a different approach to training and deployment are required.

Look at the seasonal demand of your industry and reflect on the best time to make operational improvements, you will find that the off season is often the best time to build capability in your core workforce and implement new systems and processes. The peak season provides the opportunity to monitor and finetune processes.

We often get feedback that this type of program will not work in the seasonal sector because of the high number of casual staff that is employed in the peak season.

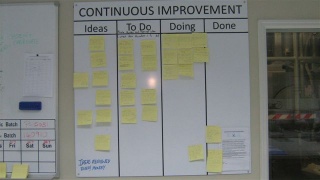

This is even more reason why an organisation needs to use the tools and techniques provided in the Competitive Manufacturing program. Standard Work is a key element of any process, developing easy to use training tools such as Visual Standards and One Point Lessons accelerate the training of new staff or last years temporary labour reducing the supervision requirement and enabling them to be productive sooner. Quality, productivity, safety, staff and customer satisfaction are all increased whilst reducing operational costs – a win-win for everyone.

Frucor Beverages (Wiri, Auckland) have been deploying Competitive Manufacturing for the last four years, and have now developed a training pathway with Competitive Manufacturing as a key part of their manufacturing strategy.

Philip Penhale – Optimisation Co-ordinator stated “The key to a new approach is harnessing every staff member’s insights, energy and talent to eliminate “non-value activities? from the workplace as well as giving teams the opportunity to take ownership of their work. We wanted a programme that would challenge, develop and help us to see new possibilities we had not been able to see for ourselves!”

Each year Frucor assess their Competitive Manufacturing progress using a benchmarking tool and define the following years objectives and program format. Training occurs between March and August each year and Rapid Improvement Events are used to sustain the initiatives and further embed the knowledge gained.

Fiona Wikaira, Production Development Manager describes the program as follows “The CM qualifications are only one of the tools to creating a culture that we want. Creating a culture requires a critical mass, and most people are not managers, hence our focus on the shop floor. Using rapid improvement events with appropriate tools to help the staff was successful in engaging the staff and a great result, while the qualification is value add to the individual.”

The meat sector is often described as a “disassembly” industry rather than an assembly industry, the Dairy sector is not too different – both sectors take a raw product, break it down into value added components, repackage and then distribute the products to market.

The meat sector is often described as a “disassembly” industry rather than an assembly industry, the Dairy sector is not too different – both sectors take a raw product, break it down into value added components, repackage and then distribute the products to market.

When applying the Lean Wastes to these sectors some additional parameters need to be used – the key is extracting maximum value from the raw material, whilst reducing non-value adding activities and costs.

Carl Ammon. GM for NZITO, supports this by saying “the CMI (Competitive Manufacturing Initiative) program has been a very useful tool to help companies build a positive climate for staff involvement in productivity improvements. We have seen some significant gains from the use of lean and other tools to drive innovation and savings in bother the dairy and meat industries”.

Companies in the Dairy Sector that have been involved in the Competitive Manufacturing program include Fonterrra, Tatua Dairy, Kapiti Fine Foods and Westland Dairy. All have taken very different approaches.

Fonterra have used the program to recognise the work that had already been implemented as part of their Operational Excellence program – staff were assessed based on the projects that had been implemented and then awarded the appropriate level of qualifications – Level 2 to Level 4. The Manufacturing Excellence Coaches were awarded a Level 4 Facilitation Strand.

Tatua Dairy and Westland Dairy have taken a different approach starting with a Diploma level. This has enabled the key decision makers to develop the strategy and awareness prior to deploying the concepts to the workforce using Level 2 (operational strand) and Level 4 (Team Leader level) units of competency.

This methodology provides alignment with the business objectives of the organisation and avoids the error of training from the ground up that many other organisations make – Competitive Manufacturing programs must align with the business strategy to provide maximum results. Use the senior team to define the right things to do, then use the workforce to do the right things right.

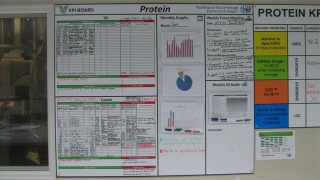

Competitive Manufacturing is relatively new to the meat sector with a number of pilot programs being undertaken in 2009 with dramatic results. One sheep meat processing plant in the South Island identified savings of $454,734 with just one project using Root Cause Analysis techniques. The same site has also implemented 5S, Kanbans, Visual Management Boards, Visual Standards and Pull systems and is looking at significantly changing the way they process in the coming meat season. Based on the results of this pilot initiative the company expects to expand the program into their other operational sites.

The Industry Training Organisations – Competenz and NZITO provide training subsidies for companies implementing Competitive Manufacturing initiatives.

nextSTEP

Visit: www.improvegroup.co.nz