Hand in Hand with a Robot

Since their introduction quite a few years ago, it has become hard to imagine industry without robots.

Their strengths – power, quickness and stamina. Their limitation – they can only flex their muscles in separate cells for safety reasons in most cases. The future – an increasing number of safety barriers will fall. The reason is that modern technology is providing such a high degree of safety that people and robots can work hand in hand.

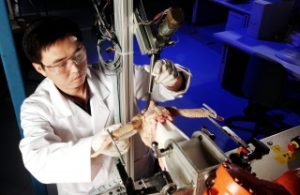

The development of “safe robots” enables a space-saving cell concept without rigid barriers on one hand.

On the other hand, it opens the door to new applications involving people and robots, for example, in installation, medical technology and the service sector.

Various colleges and institutes have worked out basic principles for this over the years, which link sensor technology with control and process control engineering as well as mechanics and consequently create new automation possibilities.

The way into industrial practice is also being smoothed by the norm ISO 10218-1 with respect to the safety aspects of man-robot cooperation (also referred to as human-machine collaboration). This ISO contains safety requirements for industrial robots, so that people and robots can work together in a defined work area without spatial separation using safety barriers or light grids.

The Fraunhofer Institute for Production Technology and Automation (IPA) in Stuttgart provides most of the active research dealing with the safety aspects of man-robot cooperation.

Martin HŠgele, Department Head of Robot Systems, believes that enormous potential has become available with the standard: “Man-robot cooperation makes it possible to combine the strengths of people and robots and consequently to automate processes, which were previously not economically feasible.

‘People have high cognitive skills, are creative and can adapt quickly to complex situations. On the other hand, robots have untiring repetitive accuracy, even when there are heavy loads. Thanks to cooperation, workplaces can be designed ergonomically and costs can be reduced overall, thanks to higher degrees of automation.”

The German Center for Air and Space Travel (DLR) is also putting this principle to work. The institute is leading worldwide in the area of safe man-robot collaboration.

For example, they have conducted biomechanical / medical injury investigations with the goal of developing a “standardised crash test procedure” for robots similar to the automobile sector.

One highlight at the institute is a lightweight construction robot, which represents successful technology transfer.