Free 3D minibike model rides onto the web

A free 3D CAD minibike model has been launched by Competenz under its Tools4Work programme for schools. It is available online as a PDF, enabling it to be used on any computer that has Adobe Acrobat, and can be downloaded at tools4work.co.nz

A free 3D CAD minibike model has been launched by Competenz under its Tools4Work programme for schools. It is available online as a PDF, enabling it to be used on any computer that has Adobe Acrobat, and can be downloaded at tools4work.co.nz

The 3D CAD (computer-aided design) model was produced by Competenz, the industry training organisation for the engineering industry, to support students and teachers with the in-school minibike programme, where students purchase a minibike kitset and assemble it, welding the frame and adding their own engine, suspension, steering and bodywork.

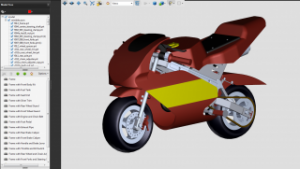

The 3D model lets students pull apart and re-assemble the minibike on screen. They can rotate the bike to view it from any angle, zoom in on a section, or isolate different parts, for example, the user can isolate just the frame and fuel tank. It is also possible to render different parts transparent to ‘see inside’ the bike, or to view the bike as line-art.

A model-tree function means bike parts can be removed and replaced, right down to the smallest nut and bolt. Pre-set views also isolate parts one-by-one, relative to the frame. Click on any part or on the model-tree, and the model-tree will tell the user what that part is, which means users can identify and learn the names of all the parts very easily.

The idea for a 3D model resulted from Competenz staff attending the National Secondary Schools Minibike Grand Prix at Manfield last year. They fully understood the enthusiasm the students and teachers had for building the bikes and learning mechanical engineering skills, and were keen to support that passion.

The budding young engineers are supported throughout the process by learning resources from Tools4Work. “The minibike programme gives the students practical hands-on skills like welding, which can help them progress into a trade when they leave school,” says Competenz Trades General Manager, Fiona Kingsford. “They actually gain unit standards towards the National Certificate in Mechanical Engineering Technology Level 2. Tools4Work’s association to Competenz means these credits are transferrable to a Competenz-managed apprenticeship. The 3D model is proving to be an excellent tool to help students, boosting their passion for the minibike programme.”

The Tools4Work programme is a catalyst for preparing young New Zealanders for a rewarding, productive and prosperous career in engineering. Tools4Work provides students with a seamless, fully resourced learning pathway; from positive outcomes and achievement in school, to trade training and qualifications in the workplace.

The minibike project gains students unit standards towards the National Certificate in Mechanical Engineering Technology (Level 2). Tools4Work’s association to Competenz means these credits are transferrable to a Competenz-managed apprenticeship.