Custom toolkit of the future

The world offers a wild number of tools to the modern tinkerer. Yet the perfect tool never seems to be within arm’s reach, or available at all.

The angle of the handle is off, the fitting imprecise, or the size awkward. How convenient it would be if we could fashion our own adaptation from clay, or styrofoam, or duct tape, throw it in a bag of sand, and pull out a solid, working version.

That future is here . . . or nearly so. Researchers at the Massachusetts Institute of Technology’s (MIT) Distributed Robotics Laboratory, Cambridge, MA, have devised a self-sculpting sand that will duplicate whatever object is thrown at it, or into it.

That future is here . . . or nearly so. Researchers at the Massachusetts Institute of Technology’s (MIT) Distributed Robotics Laboratory, Cambridge, MA, have devised a self-sculpting sand that will duplicate whatever object is thrown at it, or into it.

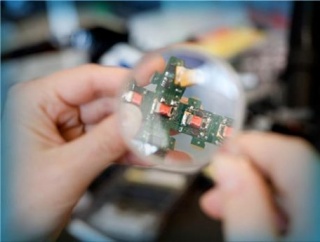

Each grain (or module) is a cube filled with processors and electropermanent magnets. The cubes do not fidget about to assemble themselves into whatever new shape is demanded of them; individual mobility would add an entirely different engineering headache. Rather, they start as a latticed block, and then learn from their neighbours the shape of any object placed amidst them. They pass along messages as to which ones should stay together and which should fall away. It’s more akin to a sculptor “removing the excess material, to reveal the shape that’s always been underneath,” says Kyle Gilpin, a graduate student at the lab who led the project.

A previous edition of the module measured 1.7 in per size. The current version is 12 mm. Shrinking them meant losing room for connectors, so at the moment they only work in two dimensions. “In the long run we would like a module approaching a millimetre in size,” says Gilpin “You can create objects with much higher resolutions.”

Smaller means stronger as well. Where a single module of the 1.7-in version could support a chain of 17 additional modules, the newer cubes can support 85. A newly assembled object would also be stronger thanks to the many additional connecting points.

When the millimetre-high modules become a reality, it will take a good 250,000 of them to make something the size of a claw hammer. Those looking forward to making one perfectly tailored to their grip better hope the price comes down. Currently, the modules cost about $350 each to produce.

Being filled with processors means that the tools the modules make could be smarter than your typical bag of hammers. Inside the body, for instance, they could form a kind of scaffolding at sites of damaged tissue or bone. They could then transmit information about the progress of healing to a doctor.

External tools could be smarter as well. A torque wrench, for example, could be programmed to shear apart when a desired torque is reached. Then the pieces could be stuck back together for the next bolt. “All this is looking into the future,” cautions Gilpin. “Right now the modules aren’t strong enough to apply a torque. We’re at millinewtons.” But he estimates that we’re only five or 10 years away from having applications for his modules.

External tools could be smarter as well. A torque wrench, for example, could be programmed to shear apart when a desired torque is reached. Then the pieces could be stuck back together for the next bolt. “All this is looking into the future,” cautions Gilpin. “Right now the modules aren’t strong enough to apply a torque. We’re at millinewtons.” But he estimates that we’re only five or 10 years away from having applications for his modules.

The self-assembly concept is not totally new. But previous versions needed each module to communicate with a computer, which would send back a signal telling each module where it needed to be. That meant that a small handful of modules would end up doing a large amount of processing as the messages were passed along to the controlling computer and back.

Now the modules do it all. “The algorithms run on the modules themselves,” says Gilpin. “You don’t need a computer, or a lab, or external power. You just need your bag of modules.”