Designing and troubleshooting 802.11ac networks correctly the first time

There is now a range of new 802.11ac features in AirMagnet Survey PRO/Planner and AirMagnet WiFi Analyser PRO to help organisations optimise their migration or co-existence path to the new 802.11ac technology standard.

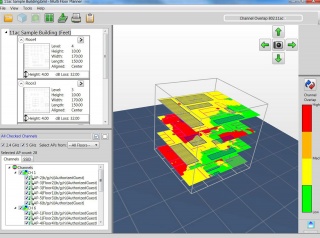

With new modeling applications, toolkits, and the industry’s only 3×3 portable capture and analysis capability, businesses can now leverage the industry’s first complete wireless lifecycle solution to design, deploy and troubleshoot 802.11ac networks accurately, quickly and more cost effectively.  As enterprise networks rely more heavily on Wi-Fi networks and increasingly face bandwidth and capacity challenges, IT is transitioning from the 802.11a/b/g/n wireless standard to Gigabit 802.11ac for more reliable connections, better performance, and higher capacity. Independent research firm Infonetics Research estimates 802.11ac access points (APs) could well account for three-quarters of access point shipments by 2017.

As enterprise networks rely more heavily on Wi-Fi networks and increasingly face bandwidth and capacity challenges, IT is transitioning from the 802.11a/b/g/n wireless standard to Gigabit 802.11ac for more reliable connections, better performance, and higher capacity. Independent research firm Infonetics Research estimates 802.11ac access points (APs) could well account for three-quarters of access point shipments by 2017.

But just moving to 802.11ac will not solve all IT challenges. According to Gartner, “More bandwidth is good, and 802.11ac can better support high transaction dense environments; however, this does not solve the underlying problem of poorly or inadequately implemented WLANs.”**

Wireless engineers and system integrators are already facing challenges integrating new equipment and ensuring deployments meet and maintain the Gigabit Wi-Fi standards. However, with the AirMagnet tools, the users are assured of designing and deploying networks that “simply work” and with the maximised performance possible. To help address these challenges, AirMagnet Survey PRO, the industry’s most accurate wireless design and site survey solution, and AirMagnet WiFi Analyser PRO, the premier solution for mobile auditing and troubleshooting Wi-Fi networks, now include 802.11ac functionality to help IT teams effectively phase new wireless infrastructure into existing WLANs without blindly performing a 1-to-1 rip-and-replacement of existing equipment.

The AirMagnet tools also let IT teams solve 802.11ac network issues correctly the first time, which prevents costly repeat visits and, more importantly, minimise user downtime.

802.11ac technology also places greater capacity demands on an organisation’s wired infrastructure, which means they must validate the capacity and quality of their Ethernet backbone before any rollouts. Fluke Networks not only offers market-leading Wi-Fi solutions with its AirMagnet tools, but also wired analysis solutions such as the OptiView® XG Network Analysis Tablet, OneTouch AT Network Assistant and LinkRunner Pro, which verify the readiness of the wired backbone to support Gigabit Ethernet.