Epson launches N6 compact 6-Axis robot and hollow force sensor

Epson has launched the new N6 compact 6-axis (vertically articulated) industrial robot and the SH250LH, a new force sensor with a hollow design.

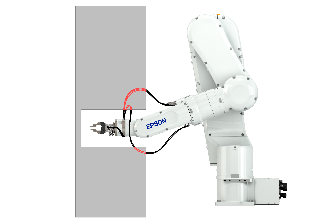

Epson’s N series of compact 6-axis robots perform tasks in tight spaces more efficiently than other robots because of a uniquely engineered “folding” arm.

The N6 has a longer arm (1,000 mm) and can handle higher payloads (6 kg) than Epson’s previously released N2 and is ideal for loading/unloading small electronic products and automotive parts into/from test equipment.

It is also perfect for shelving/unshelving medical products and much more and has a smaller installation footprint than earlier 6-axis robots and can reach a wider range of places, from the top shelf to the bottom. These features increase productivity and the efficiency with which factory space is used.

N6 Features

1. The unique arm structure and arm length give the N6 a small installation footprint while allowing it to reach high places.

Taking advantage of the N series’ folding arm design and a long (1,000 mm) arm, the N6 can access locations that are higher than those that can be reached by the N2 and by Epson’s 900-mm class 6-axis robots (the C4L and C8L). Users can exploit these features by laying out factory shelves and equipment vertically instead of horizontally to enable the N6 to use previously wasted vertical space.

Installation space (blue section) reduced by 75%

Even with an arm length of 1,000 mm, the N6 can reach objects at the same height as the C8XL, Epson’s 1,400-mm class 6-axis robot. Moreover, because the N6 can be installed closer to shelves and equipment than a 1,400-mm arm, the installation space can be reduced*2 by about 75%. In addition to installing the N6 in narrow spaces and inside equipment where robots previously would not fit, users have the freedom to consider more compact factory layouts.

2. Hollow arm provides storage space for cables and hoses

A hollow arm design is employed to allow cables and hoses to be routed through the centre of the arm at joints #5 and #6. Routing the cables and hoses to the end-effector through the arm reduces the risk of damage and disconnections that could occur if the cables and hoses were to get caught or pinched when accessing narrow openings to shelves or equipment. The robot can also be set up more easily because you no longer have to take into account the amount of wrist rotation (the wrist is the moving part between joints #5 and #6) when routing cables and hoses.

Conventional routing method cables and hoses routed to the end-effector through the arm.

Like the arm, the optional new SH250LH force sensor also employs a hollow design, so cables and hoses can be neatly routed through the sensor as well as the arm.