ZW3D for one man operations, SMEs and corporates

Affordable CADCAM must deliver:

• Enterprise-level mechanical design and engineering system.

• Cost effective ownership.

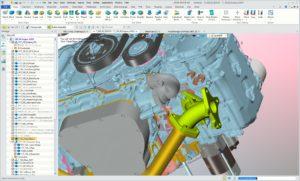

ZW3D CADCAM is truly integrated. It’s core objective is provide unified environment from concept design to final manufacturing. This is achieved with a powerful proprietary hybrid 3D CAD and CAM kernel.

Not only is complex surface generation and manipulation at the centre of the design, the modelling database is object oriented improving speed and providing flexibility.

ZW3D does not distinguish between solid, surface or wireframe methodology. All ‘objects’ are usable as a source for developing geometry. The edge of a solid can be used as the profile for a surface or solid extrusion in any direction, as a path for a sweep, the edge of a loft, part of a UV curve set, the path for a distributed pattern of any other object from points through to components.

Even if the resulting surface or shape is non sensible in the real world, ZW3D will accept this as a valid object and allow you to continue modelling without a hiccup.

CAM users benefit massively from having ready access to high level modelling capability. Comprehensive translators are standard. Some common file types can be used directly.

ZW3D Point cloud tools, including STL manipulation can handle millions of points, reduce data and apply complex smooth surface meshes. Resultant surfaces are then used as part of the solid model for shape generation. No additional software or plugins required.

AutoCAD users use existing drawings to develop 3D models. One user is currently migrating 2,500 2D sketches to 3D parts. Assembly anomalies have been discovered and resolved. Now they can build and document assemblies with drawings, cross sections, BOM and even instructional explode and unexplode videos.

Sheet metal, weldments, morphing , patterning and direct editing tool suites are also standard within ZW3D

Assembly centric modelling is a strength. ZW3D allows any geometry from any component in an assembly to be used to generate further geometry associatively or otherwise.

Parametric linked assemblies are normal. Easy configuration management and customisation of embedded data in models further adds to long term gains for product manufacturing.

ZW3D provides choice in file structure between project based single files containing drawing, components, assemblies and CAM plans. Or a single object per file environment. Managing projects, versioning and moving projects is easy and uncomplicated.

CAM operators enjoy a drag and drop approach to building CAM plans. From 2 axis to 4-5 axis processes are logical and consistent. CAM operators can dive right in and get started with little effort.

Sound too good to be true? ZW3D is available on a 30 day full featured trial basis. File size is under 900Mb including full CAM and installation takes about 15mins.

Contact Graceland Technology after downloading so you can get a head start and discover the level of support available. www.zw3d.co.nz