3D modelling important in design of New Zealand’s Pūhoi to Warkworth motorway

Design Joint Venture (DJV), a collaboration between engineering consultants, Beca and Tonkin + Taylor has highlighted the power of Seequent’s Leapfrog Works 3D geological modelling software in the design of a motorway extension from New Zealand’s Pūhoi to Warkworth.

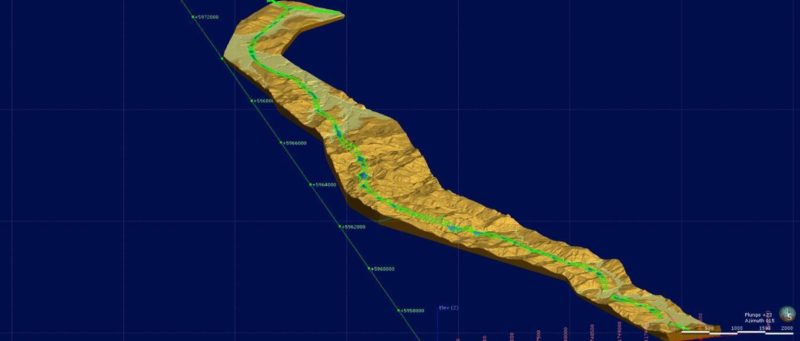

With an estimated cost of more than NZ $700m (including maintenance over 25 years), the 18km Pūhoi to Warkworth motorway extension includes a road corridor that cuts through steep hills and valleys, and the creation of seven bridges including three viaducts. Combine this with the cutting of 7 million cubic metres of earth (and the filling of 5 million), and the challenge of soft alluvial sediments – and it’s easy to see why a project wide ground model is essential as a basis for geotechnical design, and to mitigate project risk

Meeting population demands

As the population of Auckland reaches over 1.5 million, and the demand on the Northland area increases, the region of Warkworth is classed as a growth centre. The number of cars travelling the route daily is set to rise from 19,700 in 2012 to 31,300 in 2026 – the extension will provide a better connection with all of the associated safety and traffic flow benefits.

The design work was subcontracted to Design Joint Venture (DJV) a collaboration between engineering consultants, Beca and Tonkin + Taylor. Seequent’s Leapfrog Works, which is specifically designed for the Civil Engineering and Environmental industries, was used as the 3D geological modelling software to more accurately define the geology.

Chris Monk, Engineering Geologist, Tonkin & Taylor, says, “There were three areas of focus. North, which showed low-lying topography; Central, which has significant cut and fill embankments and; South, which contained two viaduct structures. It was important we could use a modelling tool that worked flexibly around the different geology and surface types to give accurate outputs. We modelled 210 cone penetration tests (CPT) and brought in data from 420 boreholes, 355 hand augers and 220 test pits.”

Working in dynamic 3D

Detailed design started in October 2016 and is ongoing. The team started collecting ground investigation data and used this to input into their 3D geological Leapfrog model. Leapfrog Works’ dynamic and continuous modelling transformed the way that the Geotechnical team worked.

Using Leapfrog Works meant geological surfaces could be mapped by a geologist, rather than engaging a CAD technician to work alongside a geologist, resulting in a smoother workflow, and faster turn-around times. As project engineers needed sections, they were able to go straight to a single point of contact to quickly create the desired section – saving time and reducing the effort in having to re-produce work.

Stuart Cartwright, Senior Engineering Geologist, Tonkin + Taylor, comments, “Leapfrog really helped us on what has been a significant and challenging project. The length of the proposed motorway and its alignment through such steep topography made the ground model development challenging.”

The Geotechnical team were able to leverage the great visualisation of Leapfrog Works to bring together and better communicate across such a wide range of project stakeholders including the Construction Joint Venture (CJV) team, quantity surveyors, surveyors and geotechnical engineers and bridge designers.

“By being able to show the model in 3D and cut sections at any desired location instantaneously enabled others to visually understand the geological conditions of the site with much better clarity. We collaborated much more as a whole project team as we were able to hold informal review sessions/workshops to show progress. In the past we would have gone with paper sections, but the 3D model outputs and graphical interface changed the way we communicated and collaborated,” says Cartwright.

Minimising the cut and fill footprint

Leapfrog was initially used by the DJV in the tender phase to create a 3D geological model of the route. The model was then imported into the Bentley ‘OpenRoads’ civil design software. This allowed the slope profiles and cut and fill quantities for different alignments to be quickly and easily compared and for optimization of the earthwork’s mass-haul to assess the most cost-effective alignment.

Understanding the material makeup of the mass-haul balance is crucial for minimising the cut and fill footprint. This not only reduces waste, but being able to understand earth composition means that extracted earth can potentially be used to fill in another part of the site, saving time and money. Environmental impact such as tree removal can also be minimised

Stuart Cartwright comments, “The contact surface between the weathered Pakiri Formation soil and underlying unweathered rock, was critical for assessing likely cut slope profiles and excavation footprints, Leapfrog made this process much easier to complete.”

Looking forward

As major infrastructure projects become increasingly large and complex with multiple stakeholders, having a 3D ground model to support the understanding of the geology allows geotechnical teams to improve efficiency of design. Easily maintaining a dynamic model over the course of the proposal and design is transforming the way ground engineers are working. This is a real step forward to enabling the civil engineering industry to become more responsive in an increasingly digital world.

“Having a dynamic model that evolves as new data is provided has saved the team time from not having to recreate a new model every time, leaving us more time to focus on analysis,” says Monk.

The motorway is expected to take 5 years to build and will be open to traffic in late 2021.