Mastercam 2019 Lathe a comprehensive turning software

From accepting and programming any CAD file to Dynamic roughing and precision finishing, Mastercam 2019 Lathe provides a variety of techniques to turn all of your parts exactly as you need them. Mastercam 2019 Lathe features a new Tool Designer, Mill-Turn Environments, Multiple Plunge, and so much more.

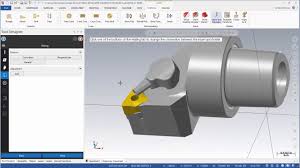

3D Tool Support

Build tools from 3D STEP models using the new Tool Designer. The Tool Designer is a function panel with tab-style navigation, providing a structured workflow that is similar to using a wizard. You can define tools, assign them to operations, and view them when running Classic Backplot and Mastercam Simulator.

Mill-Turn Environments

Mastercam 2019 allows Lathe users to run select Mill-Turn machine environments, giving users the productivity benefits of Mastercam’s Mill-Turn programming environment. Experience automated job setup and part transfer, full machine simulation, and simplified programming of C/Y axis toolpaths.

Mastercam 2019 allows Lathe users to run select Mill-Turn machine environments, giving users the productivity benefits of Mastercam’s Mill-Turn programming environment. Experience automated job setup and part transfer, full machine simulation, and simplified programming of C/Y axis toolpaths.

Multiple Plunge

The Lathe Groove toolpath includes a Multiple Plunge option which allows you to rough out a groove with rib cuts. This is beneficial when you are concerned about tool deflection. Consistent tool pressure can result in better chip control, and more even tool wear. Multiple Plunge gives you the option to machine the ribs with a more aggressive feed rate than the initial plunges.

Also available in the Mastercam 2019 Lathe is:

- Improved support for cross-centerline turning.

- Support for Swiss machines. Swiss users with active Lathe and Mill/Mill 3D licenses can now take advantage of familiar Lathe and Mill toolpaths (available in the United States).

- Full integration of the PrimeTurning toolpath. Mastercam 2019 features improved tool libraries, including 3D tool libraries and the introduction of 3D tool support.