Gripper excels in handling cylindrical objects

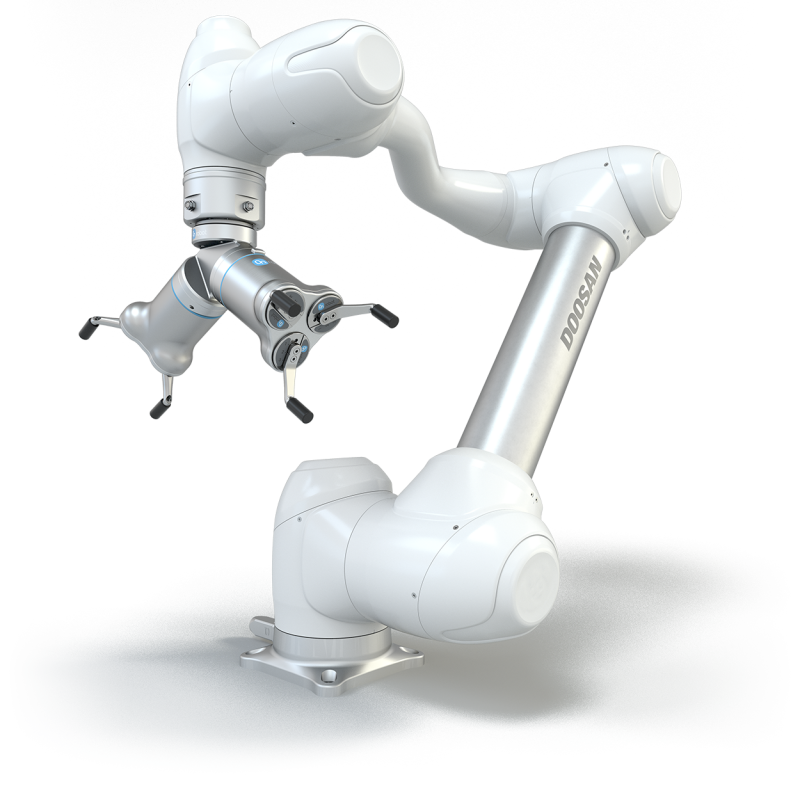

OnRobot’s 3FG15 three-finger gripper with a 150mm stroke is a powerful alternative to bulkier and less-flexible three-finger grippers currently on the market – a unique solution.

The new gripper excels at heavy-payload machine-tending applications that require high precision and flexible handling.

The 3FG15 makes previously hard-to-automate precision handling of cylindrical parts easy to program and deploy and provides flexibility for a wide range of part sizes.

It was developed as a response to existing pneumatic three-finger grippers that are bulkier and less flexible. OnRobot has long defined the market for electric parallel grippers with the RG2 and RG6 series, and this three-finger gripper allows users to deploy applications faster with highly accurate, fixed positioning.

The 3FG15 gripper has a maximum stroke of 150mm that can easily handle multiple processes. The innovative three-finger design with a 15 kg (33 lb) payload provides a strong, stable grip for both form fit (internal) or friction fit (external) gripping, adding flexibility to any implementation.

Ideal for CNC machine tending

The gripper’s design, specifically developed for machine-tending tasks, automatically centres workpieces, resulting in a strong, stable grip and precise placement in machine chucks. With a gripping force from 10 N to 240 N, the 3FG15 competes with much less flexible finger grippers.

The gripper is also ideal for packaging and palletising applications, and is seamlessly compatible with any major collaborative or light industrial robot arm through OnRobot’s new award-winning One System Solution, the platform that provides a unified mechanical and electrical interface between the robot arms and any OnRobot end-of-arm tooling (EoAT).

3FG15 Features:

Precise stable grip with automatic centring

Large 150mm stroke for parts from 20mm to 150mm

Form fit (internal) and friction fit (external) gripping

15kg payload

Weight 1.15kg, gripping force 10-240 N

Fast, flexible deployment

The EoAT market in Asia Pacific, excluding Japan, (APEJ) has been growing exponentially as developing countries transform their industrial landscape with emerging technologies. In 2018, APEJ EoAT sales accounted for over 51 per cent of the global market[2].