Cradle to Cradle, Life Cycle Assessment and Circular Economy: A love triangle

Life Cycle Assessment, Circular Economy and Cradle to Cradle are seen as interchangeable terms by some, and totally separate concepts by others. As is the case with most things, the truth lies somewhere in the middle.

A life cycle approach

Figure 1 A life cycle approach looks at all stages in the life cycle of a product.

There are similarities between Life Cycle Assessment (LCA) study, Circular Economy and Cradle to Cradle (C2C), which causes some of the confusion. However, they are different concepts- albeit with a shared approach to sustainability and problem solving within sustainability.

The common link is a ‘life cycle approach’ which considers a number of different environmental impacts such as carbon footprint and use of resources.

These environmental impacts occur across all stages of a product’s life cycle, from when the raw materials are grown or gathered to where the product ends up after it has been used. The life cycle approach highlights the bigger picture of environmental impact and can act as a great starting point for identifying and improving on environmental hotspots in the manufacturing industry.

Avoid ‘burden shifting’

An LCA study avoids ‘burden shifting’ – solving a problem in one area of environmental impact while creating a problem in another.

ake the example of cucumbers. Removing plastic wrap around cucumbers results in lower packaging impacts, but vastly increased food waste downstream. An LCA would look at this information together – and would inform you that wrapping cucumbers in plastic actually results in better outcomes for the climate.

Rethink material use

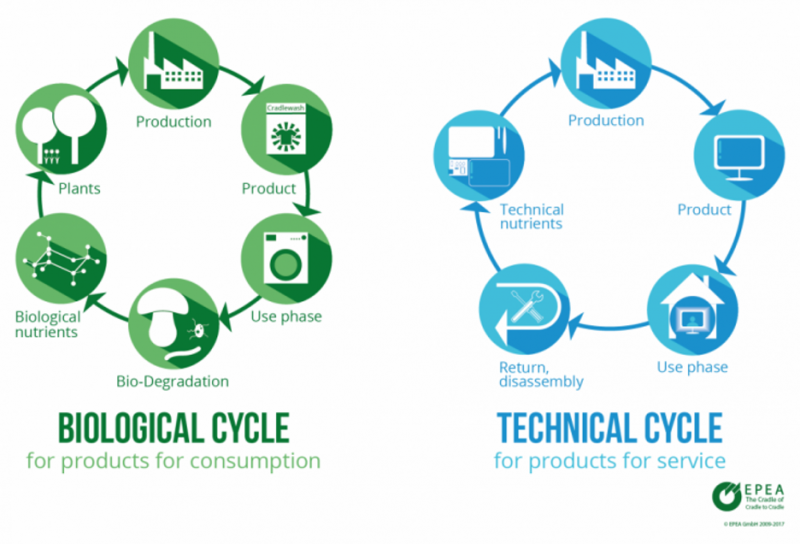

The C2C concept takes a similar life cycle approach to products but goes one step further to ensure that all materials used in production can be reused as a nutrient.

These nutrients stay in either a biological cycle where they are returned without harm back into the biosphere or in a technical cycle where the material is reutilized continuously without losing its value. In the case of a car tyre, C2C looks not only at what happens to a tyre at the end of its useful life, but also looks at the rubber dust that is left behind from everyday use of the vehicle.

This way, it accounts for the overlooked environmental impact of rubber as it leaves the technical cycle and re-enters the environment.

Figure 2 Source: EPEA GmbH

An LCA study quantifies environmental impact across a wide range of indicators, but always includes a full carbon footprint. C2C certification requires a carbon programme in place for organisations, but not necessarily a full carbon footprint. Still, these two systems are highly complementary; an LCA study combined with the design principles of C2C opens up data-backed opportunities for a truly circular economy.

The ultimate love triangle

Circular economy also looks at the reutilization of materials but is more of a high-level view, which considers ideas like the sharing economy. These three key players in sustainability combine to form the ultimate love triangle.

Some companies are already putting these ideas to good use: Look at Levi’s® using LCA studies to identify their environmental hotspots, and Mud Jeans running a ‘Lease A Jeans’ program to encourage a more circular, shared economy.

C2C certified jeans will make sure that fibres that are shed in the washing process don’t cause harm as they re-enter the environment from wastewater. The potential is limitless if these concepts are combined to approach life cycle thinking fully.

Do more good, not just less harm

We already use more resources each year than the earth can regenerate. With an increase in resource use between 1970 and 2019, the Global Footprint Network’s Earth Overshoot Day initiative estimates that as of 2019, we need 1.75 planets to support our current demand on Earth’s ecosystems.

Damaging practices don’t become positive just because we do them less; they just serve to delay the inevitable. This is where C2C stands apart from conventional thinking around sustainability with its focus on optimising positive impact. While an LCA study focuses primarily on reducing negative impact, a product’s sustainable performance can be maximized by bringing together the reliable data of quantitative LCA and C2C concepts to inform a wider circular economy.

Utilise the love triangle to ensure that we don’t simply minimize environmental impact- let’s work to eliminate negative impact completely and move towards a positive environmental footprint.

For more information on LCA, C2C and Circular Economy, visit thinkstep-anz.com.