The truth about counterfeits

~ Why you can never eliminate the risk of counterfeits entirely ~

According to the latest data from the Organisation for Economic Cooperation and Development (OECD), the trade in counterfeit goods now represents 3.3 per cent of global trade.

Unfortunately, this figure is on the rise, even as overall trade has declined. Here, John Young, APAC director at obsolete parts supplier EU Automation APAC, offers his verdict on the scale of the problem in the Asia Pacific region and what manufacturers can do to limit the risks.

Counterfeiting in industry

Counterfeiting is not a new problem, but the current growth of this phenomenon is driven by many novel factors, such as the convergence between industry and IT and new technologies like 3D printing.

Most people have some familiarity with this problem in the world of consumer goods, but industrial equipment is not immune to the risk.

In the world of industrial parts, fakes are often even harder to detect. Take an industrial motor as an example. The outer casing or housing of the counterfeit part may look perfectly fine. Even on the inside, there is very little way of detecting a counterfeit through a simple visual inspection.

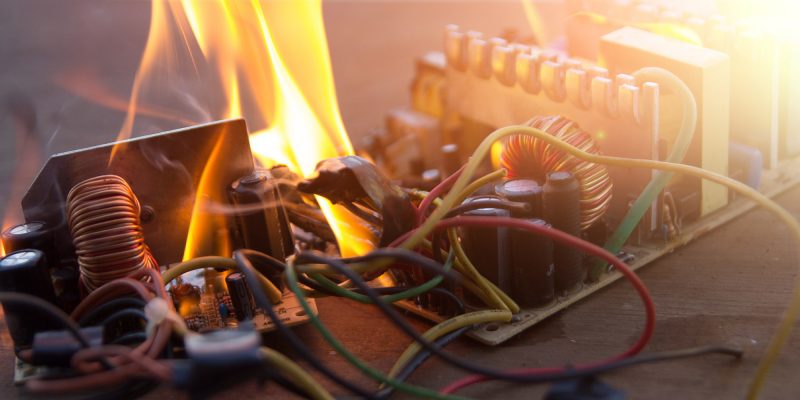

Counterfeited industrial parts are usually manufactured from poorer quality material. This reduces the life cycle of the part, increasing the risks of unplanned downtime and raising whole-life costs when unexpected failures occur.

Unfortunately, there is often little way to know definitively if the broken part was genuine or not.

Genuine parts will have been through a rigorous and standardised process of testing. Fake parts, on the other hand, do not benefit from this validation and verification process.

Labelling is one way of stamping products in a way that can demonstrate their authenticity, but unfortunately modern technology makes these labels much easier for scammers to fake.

The anatomy of the problem

The truth about counterfeits is that it is impossible to eliminate the risk entirely. That’s a controversial admission, but one that any realistic parts supplier should be willing to concede.

As the OECD figures demonstrate, the problem is widespread and deeply entrenched. Asia – and China in particular – is seen as the global centre of counterfeits.

Although it is true that a statistically high proportion of counterfeits originate from China or Hong Kong, we need a more nuanced assessment of the problem.

Asia is the workshop of the world and so we should expect a correspondingly higher volume of counterfeits to originate here.

It is also worth dispelling the myth that the US and Europe are the sole targets of this problem. Australia, Japan, South Korea, China and Hong Kong also rank prominently among the victims.

More importantly though, as has been observed by the OECD’s own experts, counterfeiting threatens to lock developing countries into the status quo.

The theft of technology, through counterfeiting, could hinder these countries from designing more of their own products.

It is a truism to say that regulations and legal frameworks often struggle to keep pace with technological change and the lag between the two is an opportunity for counterfeiters.

However, it is just as often the failure to enforce existing regulations that is the problem, rather than the absence of regulation to begin with.

As for enforcement, geographical factors can often be major obstacles. Another reason Asia is a major source and conduit for counterfeit goods is because it hosts many of the world’s largest ports.

Countries with long borders and sprawling coastlines are always going to struggle to keep fakes from entering. Malaysia is an obvious example of this in the Asia-Pacific region.

Enforcement can also be hindered by what are otherwise positive developments. For example, an unintended consequence of free trade zones is that they make rules against counterfeiting harder to enforce.

In future, technologies like blockchain might strengthen the fightback against counterfeits. In recent years though, many technological developments have simply strengthened the hand of the scammers.

The rapid growth of e-commerce provides a more loosely regulated arena through which counterfeiters can advertise and sell their products. 3D printing, for all its undoubtedly positive applications, is also a fantastic tool for creating fake parts, especially when CAD designs are freely available on the internet.

The good news

Although it is impossible for suppliers and plant manufacturers to wholly eliminate the risk of counterfeits, there are steps and measures that can be taken to constantly improve the odds in your favour.

Firstly, carry out a thorough audit of your equipment so you are aware of the expected lifecycle of each component. Keeping track of this information will allow you to make more informed judgements if you find yourself facing repeat problems.

Here’s another golden rule: if something sounds too good to be true, then it probably is. Extra low prices do not guarantee a part is fake, but it should make you more vigilant.

In the APAC region, the counterfeit market is partly fuelled by high demand for low cost parts. Unfortunately, it is the demand for these lower priced parts, along with a lack of understanding of their risks and the true cost of the authentic component, that helps fuel the market for counterfeits.

You should always check a supplier’s counterfeit policy and what measures they have in place to address the risks. A fake part may perform perfectly well for a few months but ultimately fail within half the typical lifecycle of a genuine part.

Furthermore, a reliable supplier should offer a good warranty. Depending on the length of the warranty, you can protect yourself against this risk.

Another mitigative strategy is building relationships with trusted suppliers. This is not something that happens overnight and it cannot be developed if you are simply looking for the cheapest option on an e-commerce site. It will, however, save you money in the long run.

Counterfeiters are often hard to catch because they shut down and then re-open somewhere else under a different name.

Reputable parts suppliers build their reputations up steadily over many years and have every interest in ensuring that their customers remain satisfied not just with the cost of the original transaction, but with the durability of the product and the continued service.

The trade in counterfeited industrial parts looks set to continue to grow for now. Hopefully, there will be a corresponding growth in our knowledge and understanding of the problem, alongside new technologies to assist us.

In the meantime, those in the market for new, reconditioned and obsolete parts should continue to educate themselves about the issue, demand good warranties with their purchases and build relationships with trusted suppliers.