Inflation pressure triggers uncertainty and volatility for manufacturing sector

-Rebecca Reed

Rapidly rising costs for businesses, a lack of skilled and unskilled workers, increasing inflation and shipping delays are putting huge pressure on New Zealand’s business environment and the consumer is about to feel it.

The latest Hutt Valley Chamber of Commerce Business Confidence Survey found inflationary pressure is increasing and between a third and a half of all businesses are expecting to increase their prices in the next 3 to 12 months.

It also found more than half of all businesses are expecting increased costs, yet less than 25% are expecting increasing profitability.

Covid-19 economic impacts, growing concern around government policy and labour shortages are holding businesses back nationally. The survey shows labour shortages as the single biggest barrier to business for more than 60% of businesses.

This is at unprecedented levels.

“The business environment continues to be increasingly difficult – while the economy has rebounded strongly and demand continues to be strong, the ability for firms to deliver is fraught with a wide range of risks and cost increases.

“These cost increases and risks are more widespread across business type and size as all companies try to adapt to the rapidly changing business environment,” said Helen Down, Chief Executive of Hutt Valley Chamber of Commerce.

Down says she is hearing from businesses unable to commit to fixed prices or a delivery timeline due to the totally uncertain environment.

“This time last year our survey found business owners were experiencing small increases in costs and holding prices but now costs are increasing rapidly, and the consumer is only just starting to feel it. The situation is set to deteriorate quickly when businesses are forced to not only increase prices but not even commit to a set price in the next six months,” said Down.

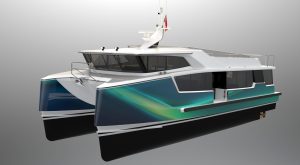

The Wellington Electric Boat Building Company is just one Hutt Valley business finding it extremely difficult to price any future work. The company, which builds electric passenger ferries in a range of sizes (16-24 metres), has achieved notable acclaim for building the first all-electric high performance passenger ferry in the Southern Hemisphere for East by West Ferries in Wellington.

Fraser Foote, the owner of the Wellington Electric Boat Building Company based in Seaview, Lower Hutt, says an increase in shipping costs coupled with severe delays of getting materials shipped to New Zealand is causing growing uncertainty around pricing for his customers.

Fraser Foote, the owner of the Wellington Electric Boat Building Company based in Seaview, Lower Hutt, says an increase in shipping costs coupled with severe delays of getting materials shipped to New Zealand is causing growing uncertainty around pricing for his customers.

“The cost of the delay is also putting us under extreme pressure. It has had a huge impact on our business – we are talking hundreds of thousands of dollars. Due to Covid, the delay in getting product to us from overseas has meant the critical path of the project has taken longer, yet we still have overheads and staff to pay.

“Previously we would order some fibreglass from American or Asia that would take 6 weeks to get here, now we are experiencing a 16-week timeframe.

“The increased costs and delays mean we can’t commit to a fixed price for our customers. The fabric of our business and society has changed for the foreseeable future. I can see this continuing on forever and I think the uncertainty of supply and delivery pricing is now the norm.”

Staying true to your clients

Helen Down says if the fabric of our business and society has changed indefinitely, businesses need to be up front and communicate with their clients to set realistic expectations on delivery times and costs.

“We are going into an environment where the pressure on business is only going to get greater and this disruption is going to be with us for years. Businesses need to now be investing in their client relationships and keeping their customers close to them.

“It’s important they try and protect their customer relationships they have worked hard to build over the years.”

Foote agrees, “the only way around all of this is to work closely with your clients, educate and be honest with them about what’s happening in the market. We are not putting timeframes on anything until we have defined scopes of work as we have no idea how long things are going to take.”

Buying local and investing in trusting relationships has never been more crucial as the country heads into an increasingly uncertain 2022.

“The economic environment is going to get harder, and some businesses won’t get through it.

They are going to need more support than they have ever had, and they are going to have to rely on solid and local relationships they have built up over the years” said Down.

Investigating new shipping models

According to Helen Down, there is no one quick fix the need to investigate and consider completely new models for local supply and logistics around manufacturing has never been more important.

“We can’t rely on the models we have built up over the past few years because they are broken – so that may mean looking at NZ owned shipping lines as a way of moving freight, having control and reliability. The bottom line is we can’t stay cut off – there is pressure on NZ businesses to move overseas because they feel they will get left behind being at the bottom of the world.

“Our market is not big enough to be attractive for global suppliers to send products to us. Our inability to achieve economies of scale is a real threat. The shipping companies are going to choose the biggest markets where they have the biggest orders.

“We are hearing that some northern hemisphere shipping lines have pulled out of the Australasian region in favour of servicing the Asia to Europe routes which is much more lucrative. We need to encourage more manufacturing here so we can supply our domestic market as well as our export market.

“Our market is too small to prioritise sending ships. We should be encouraging more manufacturing in NZ so we can supply ourselves and our markets, have control and not be as reliant on imported materials to complete projects. We are starting to hear examples of manufacturers investing in local supply opportunities.”

The future can be bright if we invest locally

While businesses scramble to meet customer demand, it is important suppliers, customers and suppliers support local whether that is purchasing local or even investing in local companies.

The Wellington Electric Boat Company is looking to commercialise their product and is in the process of seeking investors that will allow them to develop and build better products.

“We have recognised a whole degree of new technology and new mechanisms that will allow us to go into the future and build boats that are lighter, faster and more efficient. However, to do this we need funding to commercialise some of these new opportunities. But first we want to put the boat in the water and prove the technology that we have been developing is there.

“We have recognised a dozen new areas where we can take what we have learnt and use that expansion to move into different markets and create a more affordable and better product in the future,” said Fraser Foote.

The company’s development of the first all-electric ferry in the southern hemisphere proves innovation is alive and well in New Zealand.

“We have had such a great reception from people all over the world. Everyone is amazed with what we have achieved. It came down to finding the right group of people who all had different skillsets and worked together as a team to come up with this ground-breaking technology.

“Once we get the boat in the water in the next few months, we know it will put New Zealand on the map and hopefully encourage more investment so we can develop the technology even further and make electric boats more commonplace in our country.

“The flow on effect for investing local is obvious – increased employment, work for companies supplying parts for the product and more money in the domestic economy.”