The Factory Ceiling

-Georgina Fenwicke, Tell Frankie

There is much to discuss about the Factory floor and for good reason. The operational layout, the transport plan, proximity to the inwards and outwards doors, the racking config. All of these drive greater productivity and operational efficiency in a building.

However, little is often mentioned about the Factory ceiling.

Long run steel roofing. Bitumen. Tiles. Clearlite. There’s a real mix of roofing products used in New Zealand’s Manufacturing facilities.

For Operations managers and manufacturers, the Factory Ceiling is one of the biggest capital risks and value add areas.

Consider the following opportunities:

- Increasing the roof height for an extra rack of space – occupancy of Industrial property is at all time highs as supply chains

- Regular maintenance of the roof – preventatively maintaining your roof profile is just smart business. It protects against

- Leaks and product damage

- Dust build up and contamination of product

- Longer life and depreciation costs spread out over a longer period of time

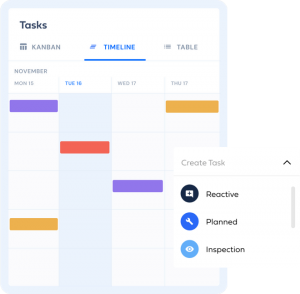

Frankie is an Operations Control Centre where your teams can get on the same page around building and machinery maintenance.

Property Operations is a mix of Asset and Facilities management, a holistic function that controls and allocates capital (CAPEX) and operating expenses (OPEX).

A day in the life of a factory manager is a moveable feast. There are issues that crop up every morning that need to be solved quickly – a roof leak, flooding, a broken door, the lift isn’t working.

There’s also the backlog of scheduled works and Inspections to be coordinated that week.

Annually, there’s a need to plan budgets, review the condition of major areas of the building and review the quality of service contracts.

Factory and Operations are facing a number of challenges in 2022:

- Availability of parts: Supply chain challenges for machinery parts are now into the months. Air Freight is driving big costs increases. A strong maintenance plan and understanding of your Parts risk is CRITICAL.

- Contractor availability and the need to reschedule: The omicron wave is going to make a few of us homebound for the next few months – we’ll need to work remotely and give contractors a bit of breathing room to schedule around their team’s capacity. Keeping on top of what has and hasn’t happened yet is critical.

- Working remotely but together: Working remotely often blurs lines of responsibility. Having a tool to clearly track who is doing what and when is critical to avoid duplicating work

All of these factors drive our product roadmap at Frankie. Frankie is cloud software for Industrious property teams to extend the life of buildings and kit to prevent unbudgeted property spend.

www.tellfrankie.com