How to successfully deliver your CRM project with Clarity, Simplicity and Certainty.

-Scott Fuller, Exception.

Article 1 :: Project Charter – Universal Buy-in

This is the first in a series of 6 articles looking at how to successfully deliver your CRM project, the rest of the series will look at:

- Architecture and Integration – The Big Picture

- Partner Selection – A Vendor vs A Partner

- Data; Data; Data – The Devil is in the Detail

- Project Management – Quality, On Time, On Budget

- Users, Usability and Usage – First, Last and Always

The purpose of the Project Charter is to engage all interested and/or potentially affected parties, solicit feedback and gain a mandate to move to the next phase. It is a Pre-liminary Business Case, a succinct document preferably with an equally succinct presentation containing:

- Purpose: Definition and those Responsible

- Benefit: Objectives and KPIs, including indication of costs

- Resources: Key Players and Roles (RASCI Model), including external parties if known

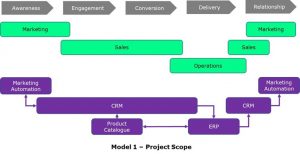

- Architecture: Technology added, impacted or replaced

- Scope: Deliverables and Key Milestones

The expected outcome is that everyone in the business is at least informed of the project scope and impact and those Responsible for the Delivery and Accountable for the Benefits are ready to drive the Project to its successful conclusion.

The expected outcome is that everyone in the business is at least informed of the project scope and impact and those Responsible for the Delivery and Accountable for the Benefits are ready to drive the Project to its successful conclusion.

The introduction of this Project ‘Vision’ gives many parts of the business an opportunity to participate in its inception and contribute to the direction. It should always be a 2-way engagement to create valuable buy-in and support.

3 x Critical Success Factors

These are CSF’s for the Charter, not the Project:

- Multi-level and multi-functional buy in

At the initiation of any project it is easy, and safer, to confine the visibility to the immediate user group and line management. However a customer management solution to be successful will require the commitment of all parts of the organisation, from Board to Basement, from Customer Facing to Supply Management, so their early engagement will optimise success.

- Measurable Business Benefits

A CRM solution will generate tangible benefits and these need to be identified early and then quantified for the business case to positively engage all future participants. The project will disrupt, and replace, existing business practices, so proactive adoption of the value of the outcomes will greatly influence success.

- Real Cost of Ownership

The accumulation of hard costs (Vendor Licences, Partner Services, 3rd Party costs) can be readily calculated. The importance of quantifying internal costs can be underestimated – Project team members time, KUG time contribution, data cleansing time, Post-delivery maintenance processes. These should be acknowledged even if not included in the Business Case.

2 x Reasons how this is Unique to Manufacturing

Sometimes it is subtle variances that make the difference in approach and each industry has its own idiosyncrasies:

- Sales Focus – Manufacturing, and subsequently Business-to-Business (B2B) sales, is very different to Retail, B2C, or even a B2B Services company. This can greatly affect the business process and therefore the solution. For example the relationships Sales Teams have with their clients are often well developed and personal and the introduction of systematic and automated processes can be seen as a hindrance and negatively perceived if they are not carefully planned and designed to sustain and enhance those relationships

- Senior Leadership Team – Due to the nature of manufacturing, especially small to medium companies, senior staff members have often come up through the business (if not owners) and therefore will be very intrenched in the way the business behaves. This can be a positive and negative depending on if the behaviours are good or bad and how receptive those Senior Leadership Team members are to change

In Summary

Clarity – The clear presentation of the Project Construct at an early stage can demonstrate the intended outcomes at a very high level and engender a positive disposition allowing Users, especially, to see and understand the need and benefit.

Simplicity – By creating a simple high-level view of the concepts to be delivered, they are more easily communicated and universally understood by all engaged staff across levels and functions

Certainty – An initial estimate of the scope, costs and business benefit to be gained allows for an early view of expectations, lodges the budget required in future periods, elicits buy-in and sets a visible direction for the project that will evolve over its duration.

For further information email: scott@xception.co.nz