Rise of the Machines – is technology really replacing humans?

– Catherine Lye, Head of Advanced Manufacturing and Export Communities, EMA

As our Smart Factory Showcase continues building momentum in the Industry 4.0, manufacturing and technology space, it’s time to share some insights into what we’ll be covering during each session.

Each Smart Factory Showcase covers several key areas of operation at Nautech Electronics. These include sales and planning, systems, connectivity, research and development, production, testing, facilities, smart business models and implementation strategies.

Industry 4.0 and the showcase are all about highlighting how a range of digital technologies enhance manufacturing performance, output, monitoring and control, keeping businesses globally competitive.

Today, we’ll consider the view that the adoption of new technologies could lead to the replacement of the human element required in manufacturing – or does it?

Many of us have seen The Terminator film series where the artificially intelligent machines become self-aware and hostile with an aim to take over the world in a post-apocalyptic future.

As Laurie Kubiak, CEO of Nautech Electronics assures us, people are always going to be necessary for the safe and successful operation of manufacturing machinery and technology. Adopting new technology is about making everyone’s lives easier, both for the company and its people.

People are required for all parts of Nautech’s operations, particularly for forward-planning, scheduling, stock management, programming and much more. They cannot be replaced. Adopting Industry 4.0 and smart technologies actually has the potential to create more job opportunities, as people become vital in ensuring maximum machine efficiency, productivity, outputs and operation.

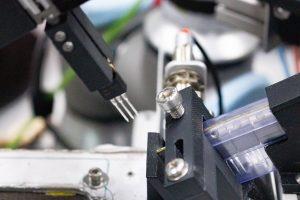

Cobots (collaborative robots) are often used to take on certain repetitive tasks that humans could do, but they are able to maintain consistency and run for longer periods. They don’t need to work a standard shift or stop for breaks. Passing on these mundane tasks to cobots also has health and safety benefits, reducing the chance of repetitive strain injury.

Cobots (collaborative robots) are often used to take on certain repetitive tasks that humans could do, but they are able to maintain consistency and run for longer periods. They don’t need to work a standard shift or stop for breaks. Passing on these mundane tasks to cobots also has health and safety benefits, reducing the chance of repetitive strain injury.

During Nautech’s quest to boost their technological capabilities, they sourced three UR3 cobots. This equipment enhanced the work they currently do by speeding up some of their manual assembly and manufacturing processes. For example, one of their cobots inputs 20,000 screws a month, each one perfectly tightened to the correct torque.

The UR robots are very easy to programme and use. Nautech have several engineers with a range of experience and their staff did not need much additional training to effectively operate the cobots. However, they did employ a robotics engineering student through a Callaghan experience grant (who now works for them full time).

The Nautech team carry out their work alongside the machines to optimise efficiency. So, in the end, this equipment did little to replace the role of a human being, it just made their role in Nautech’s operations more interesting.

In other factories, the retrofitting of cobots to automated machinery can enable increased production runs of components, thereby reducing the investment required in the purchasing of brand-new equipment.

Cobots are often a relatively inexpensive alternative compared to replacing existing machinery, and given the current labour shortage, they can often be the missing link between two machines and provide opportunities to free up staff for other tasks.

Experience it for yourself – register now!

The Smart Factory Showcase is an interactive multimedia presentation like no other. Your facilitator will take you behind the scenes at Nautech Electronics, through a digital twin of their factory, and provide a unique opportunity for you to see how they have integrated Industry 4.0 in all areas of their operations, and how it’s applicable to every sector. From cobots and sensors, through to smart dashboards, you’ll see it all!

This is your chance to see how Industry 4.0 will help your business. It’s a simple first step and is completely free to attend. You’ll walk away with the confidence and knowledge needed to take your next leap forward in adopting Industry 4.0 technologies in your business.

Here are some upcoming Smart Factory Showcase sessions:

Wednesday 17 August

Friday 26 August

Tuesday 30 August

All sessions run from 9am – 12pm at the EMA Business Hub, 145 Kyber Pass Road, Auckland.

We look forward to sharing our September 2022 dates with you very soon.

Don’t wait – register here www.industry4.govt.nz/UpcomingEvents and begin your journey.

Nautech Electronics have worked tirelessly for over 30 years to deliver their clients the high-quality electronic solutions they need. They use the latest technology and Kiwi ingenuity to establish themselves as a world-leader in electronics manufacturing and product engineering. For more information, please visit – www.nautech.com