Regulated product stewardship driving transition to a circular economy

By Trevor Tutt – GM Innovation, 3R Group

By Trevor Tutt – GM Innovation, 3R Group

Something which will affect almost all New Zealand businesses has mostly flown under the radar since it was announced during the covid pandemic. A swath of products are set to fall under regulated product stewardship for the first time in New Zealand after they were announced as priority products in July 2020.

This means, for the first time in Aotearoa New Zealand, regulated product stewardship schemes are being established for tyres, electronic waste, single-use plastic packaging, synthetic refrigerant gases, agricultural plastics, and agrichemicals.

So, if you rely on refrigeration, transport, electronics, or plastic packaging for your goods, you may be affected.

It’s a big range of products, with more likely to be announced following government consultation on ways to accelerate product stewardship in new waste legislation.

What is regulated stewardship?

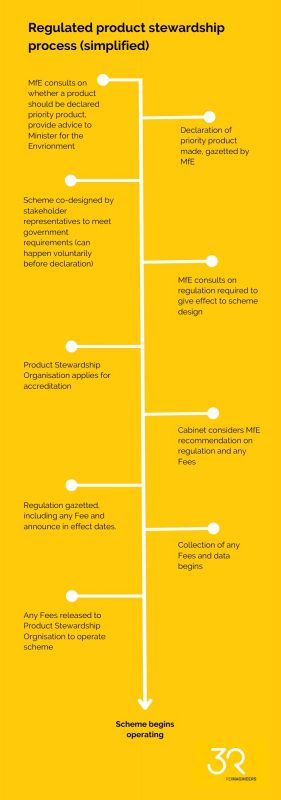

Product stewardship sees scheme members contribute towards the collection of their products at the end of life so they can be reused, recycled or properly disposed of.

This usually means a stewardship fee is charged at the point of manufacture or import and is used by a scheme to achieve better environmental outcomes. The pay-off is improved environmental performance and brand reputation, as well as reduced risk from environmental harm.

New Zealand has several voluntary stewardship schemes where participation is just as the name suggests – voluntary. These can suffer from limitations due to insufficient data and resources, and free riders – those who don’t contribute but whose products are stewarded through the scheme.

Regulated stewardship sees all of industry required to participate.

This provides a level playing field with no free riders. Schemes are therefore better resourced financially and through industry support such as knowledge sharing and collaboration. Data capture is also greatly improved.

Regulated schemes are better equipped to reduce the amount of waste a product creates at the end of life and incentivise design for reuse and recycling.

It promotes the move to a circular economy by driving efficient resource use and waste reduction.

What progress has been made?

The priority products have different timelines in terms of getting operational stewardship schemes going.

Tyres is the most advanced with the Tyrewise scheme having already been accredited by government in November 2021. The scheme, which we have been involved with since its inception, is in the trial phase and is due to roll out nationwide late this year.

We’re involved with the Battery Industry Group (B.I.G), which is working to deliver a stewardship scheme for large energy storage batteries (over 5kg). We have also worked with the Trust for the Destruction of Synthetic refrigerants (operating as Cool-Safe) on scheme design and to advance their application for accreditation.

B.I.G is currently working on ensuring it has the data needed to inform regulation and scheme design. It’s also engaging with industry – both in terms of EVs and large battery energy storage.

Cool-Safe is also working towards regulated stewardship and ensuring refrigerants can be dealt with onshore. This includes investment in a plasma arc waste destruction facility in the Bay of Plenty.

On the single-use plastic packaging front, government awarded $1 million in funding for a project to develop a regulated scheme over two years. This is being jointly led by The Packaging Forum and the New Zealand Food and Beverage Council.

Agrecovery, the voluntary scheme for agricultural chemical containers, is working towards regulated stewardship for agricultural chemicals and their packaging.

TechCollect NZ, is also working towards a regulated stewardship scheme for e-waste. They are on a timeline in which a scheme manager will apply for regulated stewardship accreditation this year.

Will your industry be impacted?

Considering the wide variety of declared products, it’s possible.

The lead time before a scheme is fully operational can be many years, but the announcement in 2020 was a signal to industry that regulated stewardship will become a major part of NZ’s waste reduction efforts.

If you are in one of the affected industries, I encourage you to make contact with the relevant organisation. In our experience the schemes designed alongside industry, and other stakeholders, will be the most effective. If you’re not, I encourage you to think about whether voluntary product stewardship could improve the environmental impact of your business.

The bigger picture

The declaration of priority products forms part of a wider landscape of waste and emissions reductions work. This includes an Emissions Reduction Plan, a proposed overhaul of kerbside recycling, planned new waste legislation, an increase and expansion of the waste levy, and bans on some plastics.

These aim to promote a shift to a circular model. Product stewardship, whether regulated or voluntary, is in our view, vital to the creation of a strong circular economy.

What’s next?

Work on establishing schemes for the priority products will only ramp up, and it’s in industry’s best interests to get involved as the design of the schemes move forward.

Work on establishing schemes for the priority products will only ramp up, and it’s in industry’s best interests to get involved as the design of the schemes move forward.

I also expect we’ll see further action by central government. Proposals and law changes to tackle climate change, standardise kerbside recycling and disincentivise landfill are yet to be implemented or are only just taking effect. We are likely to see more action too.

More and more we are seeing the social license to operate having a strong sustainability component. If they are well thought-out, designed and executed, changes to the way we deal with waste will have profound benefits for business and the environment.

3R accelerate the circular economy through the design, implementation and management of product stewardship schemes and other sustainability services. Find out more at www.3r.co.nz