Tanaka develops first high-entropy alloy powder of only precious metals

Enabling proposals tailored to customer needs through the establishment of five or more different precious metal alloy powder production methods

TANAKA which develops industrial precious metals products as one of the core companies of TANAKA Precious Metals, has succeeded in creating a high-entropy alloy powder composed of precious metals with a fine particle size of 10µm or less high crystallinity and excellent composition uniformity.

This product is the world’s first high-entropy alloy powder composed of only five precious metals: platinum (Pt), palladium (Pd), iridium (Ir), ruthenium (Ru), and rhodium (Rh). TANAKA has already established a mass production process for this product and began providing samples in October.

TANAKA has established five or more precious metal alloy powders and their production methods, which are used in this product, and obtained a basic patent in June 2023 (Patent No. 7300565)[1]. The precious metal alloy powders in this product are alloys composed only of five or more precious metal elements that maintain the corrosion resistance, electrical conductivity, and other excellent properties of precious metals.

They are micro-order[2] alloy powders that are easy to use in industrial applications. Unlike conventional nano-order precious metal high-entropy alloys, micro-order alloys are stable as alloys due to their large crystallite size, and they satisfy the original requirements of alloys, such as improved mechanical strength, corrosion resistance, and controlled thermal expansion. They are also expected to contribute to the improvement of the functions and properties of precious metal alloys, whose properties vary greatly depending on the composition ratio of the alloy.

High-entropy alloy powder

The precious metal alloy in this product is in powder form, and in addition to modeling using a 3D printer and rod forming (forming rod-shaped material by solidifying powder), it can also be used in paste form, which is often used in various circuits and sensors. Furthermore, the high strength and high heat resistance properties of high-entropy alloys are expected to be utilized in catalysts and conductive films that require high durability, among other applications.

[1] Patent related to high-entropy alloy powder granted on June 29, 2023 (Patent No. 7300565). The precious metal alloy powder in this product is defined as (1) precious metal alloy powder consisting of an alloy of five or more precious metal elements, (2) average particle size of 10µm or less, (3) crystallite size of 60nm or more, and (4) one peak observed in the range of diffraction angle 2θ of 38 to 44° in the X-ray diffraction spectrum.

[2] Order: A term used in physics, engineering, and other fields to roughly express the magnitude of a number. It represents the number of digits or degrees of a unit.

Component and surface analysis of high-entropy alloy powder

X-ray diffraction spectra of high-entropy alloy powder and various precious metal powders

About High-Entropy Alloys

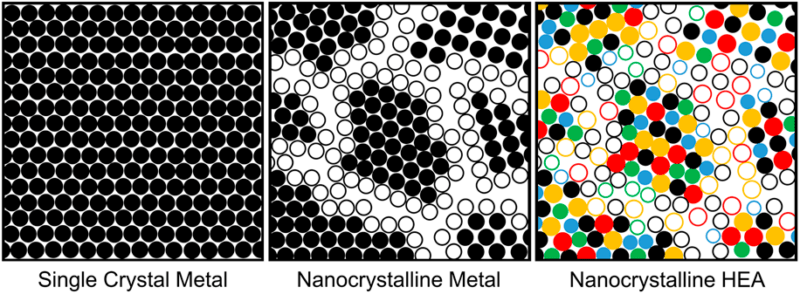

High-entropy alloys are alloys containing five or more elements in equal amounts and are characterised by the absence of major elements that make up most of the alloy. They have been attracting attention as a new category of metallic materials in recent years.

Research and development on high-entropy alloys is being actively conducted worldwide, as the properties of the metals and precious metals contained in these alloys can simultaneously produce properties such as high strength and high heat resistance, as well as the possibility of creating new properties.