Could a laser-generated plume be the next biohazard scare?

By Ruth Nicholson, Laser Safety Officer and Director at NZ Laser Training Institute Ltd

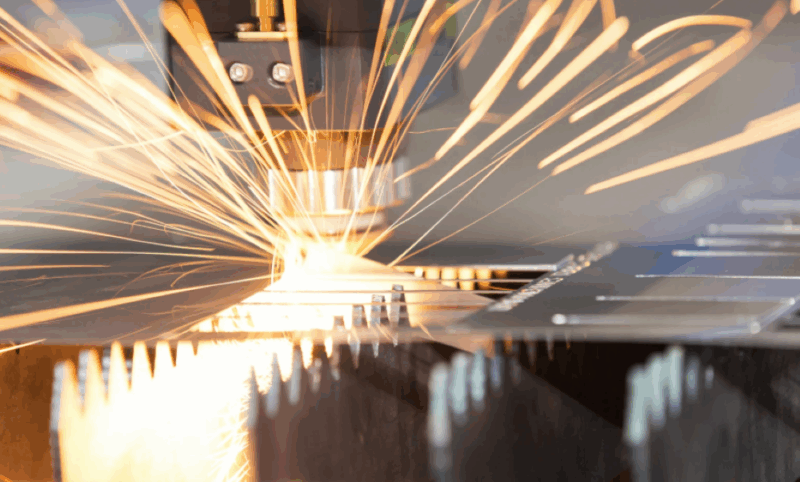

Lasers are an emerging technology used across various industrial applications such as precision cutting of metals, welding components with minimal heat distortion, or hardening to improve wear and corrosion resistance.

Unlike ordinary white light, they emit a single wavelength of light specifically designed to target materials.

When workers use lasers for welding or removing corrosion from surfaces, a laser-generated plume is created.

The plume or visible smoke that you can see identifies the bigger particles. However, it is what you can’t see that causes more hazard and harm.

The plume is a mixture of smoke, invisible vapours, and airborne contaminants that can be produced as a byproduct of laser processing, where heat sources interact with substrate materials.

Plume generation occurs with Class 4 lasers and some Class 3B lasers and can be either ‘contained’ or ‘airborne’. Each scenario presents a risk. However, the hazard level depends on how the by-product plume is managed afterwards.

This interaction between the laser and the target relies on the scientific principle that specific wavelengths of light energy can affect targets such as grease, soot, paint, rust, oil, debris, or other forms of corrosion.

Laser-generated plumes are a non-beam hazard; they are silent, subtle, and often overlooked. The contents of the plume depend on the materials being lasered and they can include carcinogenic particles, such as silica and hexavalent chromium.

Specific laser interactions can decompose materials into toxic substances, such as hydrogen chloride and hydrogen fluoride. It’s essential to emphasise that exposure to non-beam hazards can pose immediate safety threats or delayed health issues, some of which may not be readily recognised, as the hazard itself is still emerging.

Laser-generated air contaminants (LGACs) can appear in both particle and gas forms. Some of the gases are harmful and can pose health risks. For example, corrosive gases such as hydrogen chloride and hydrogen fluoride are particularly concerning.

Additionally, materials such as Parylene, PVC, PTFE, and PVDF, which are common in adhesives and coatings, contain chloride or fluoride compounds that can release toxic gases when broken down.

At best, occasional exposure might cause throat irritation, coughing, sensitive eyes, and a strong smell that seems to linger in the nose. At worst, workers might become accustomed to the smell or be unaware of it, especially with frequent exposure. Our concern is the potential health effects that this situation could lead to.

Workers exposed to laser-generated plumes face a higher risk of respiratory damage. Long-term exposure could lead to cancer, occupational asthma, and breathing difficulties. To be clear, any exposure may be harmful so eliminating all exposure to laser plumes is highly recommended.

To safeguard workers, the hierarchy of hazard controls should be applied. Realistically, PPE is likely to be the quickest and most accessible solution to implement. Laser PPE should include laser safety glasses matched to the wavelength, with a correct optical density (OD) rating.

Ensure a proper fit and possibly supplement this PPE with a full-face shield for additional radiant heat protection, when laser welders are in use.

To protect the worker from airborne contaminants, personal respirators and powered air purifying respirators (PAPR) are highly recommended. Local exhaust systems at the source, combined with a fresh air supply into the workspace, are ideal.

A hazard often overlooked is not only neglecting to wear PPE but also failing to clean, replace, or maintain it. For respirators to be effective, they require proper fit testing and filtration that is suited to the specific particles and plume characteristics.

The official researchable term is ‘Laser-generated air contaminants’ (LGACs), and it is encouraging to see the number of articles increasing. Most are credible and authored by occupational health and safety professionals, including occupational hygienists.

The topic has been actively discussed at International Laser Safety Conferences, and we find this very encouraging.

Industry experts suggest that handheld lasers used for cleaning, ablating, or removing corrosion are among the most hazardous. This includes lasers used for paint removal, which also pose high risks. Laser welders may produce less plume than traditional welding fumes. However, the plume, albeit in smaller quantities, remains a recognised hazard.

If your workplace is already using a laser capable of producing laser-generated air contaminants, or you are looking to introduce Class 3B or Class 4 lasers to your workplace, we recommend laser safety education for your team.

Professional guidance on the correct and most adequate PPE and safety controls ensures that your workplace meets the Australian and New Zealand (AS/NZS IEC 60825 series) laser safety standards. These include the requirement for a trained person to become the nominated laser safety officer (LSO).

Laser technology is driving innovation in New Zealand manufacturing, but a proactive and health-focused approach will ensure this boosts to our global competitiveness comes with a duty of care.