Living in an apartment, near the railway line

On a business trip, I travelled on the Tokaido Shinkansen Bullet Train between Tokyo and Nagoya and, was taken by the number of apartments along the side of the track, at Bullet Train speed. And they all had one thing in common on their balcony: a dog kennel, a satellite […]

Engineering the future: What we’re seeing from the front line

By James Richardson, Commercial Manager, Caliber Design At Caliber, we work alongside some of New Zealand’s most innovative engineering businesses. With over 60 mechanical engineers seconded into client teams across the country, we get a front-row seat to the future—watching it take shape in factories, labs, and workshops up and […]

Industry 4.0 for SME manufacturers

Article 4 – from a series of 5 – From June issue, NZ Manufacturer magazine www.nzmanufacturer.co.nz -Frank Phillips, Director, Fulcrum Article 4: The Significance of Systems in Industry 4.0 and Automation Welcome to the next part of our Industry 4.0 series for SME manufacturer. We’re exploring various companies that can […]

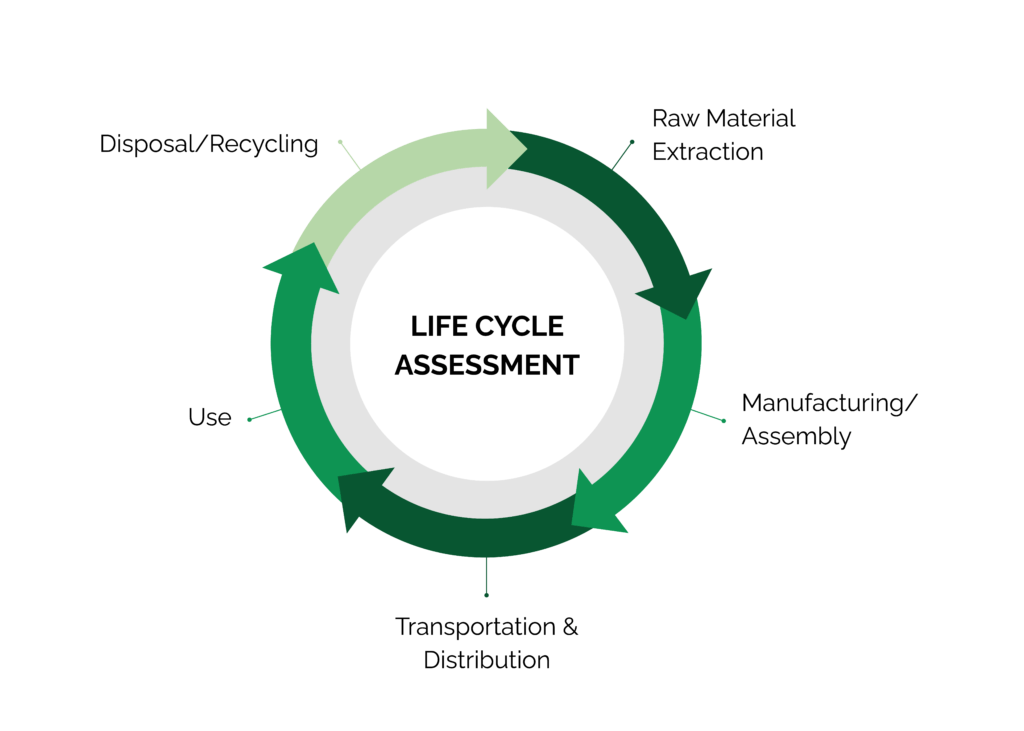

LCA: A powerful tool for change

In the early days of sustainability, we were often driven by a desire to “save the polar bears” or protect rainforests. Today, business leaders are asking a different question. It’s no longer “Is this the right thing to do?” but “Is this worth the investment?” The answer is yes, and […]

Expect to Win: Raising the Bar and Aiming for Excellence

From June issue, NZ Manufacturer magazine www.nzmanufacturer.co.nz In a Bay of Plenty workshop, the first press of the day starts up. Meanwhile, 18,000 kilometres away, its twin in Stuttgart is already changing over to the next job, 30% more parts out the door before smoko. Same equipment, same potential just […]

SouthMACH 2025: Capability Is still the differentiator

From June issue, NZ Manufacturer magazine www.nzmanufacturer.co.nz Review from Caliber Design There was a strong sense of optimism at SouthMACH this year. The energy was good. People were open, engaged, and proud of the work they’re doing. Yes, there are still challenges—but the general feeling was that things are […]

SouthMach 2025: Innovation, Excellence, and the Future Talent of New Zealand Manufacturing

From June issue, NZ Manufacturer magazine www.nzmanufacturer.co.nz -Adam Sharman,CEO LMAC Group, APAC SouthMach 2025, held at Wolfbrook Arena in Christchurch from 28–29 May, once again proved to be the South Island’s premier event for the manufacturing and engineering sectors. With a strong focus on innovation, digital transformation, and workforce development, […]

Page Macrae’s new Port Products hopper a game-changer for materials bulk handling

From June issue of NZ Manufacturer magazine. Page Macrae Engineering is one of New Zealand’s most respected heavy engineering fabrication companies, with a legacy spanning more than six decades. Based in Mount Maunganui, the company was founded in 1955 and has built a reputation for large-scale projects in tank and […]

Have you optimised your asset care strategy?

-Ian Walsh, Partner, Argon & Co NZ It’s great to see the recent government announcements allowing additional tax deduction for new assets, which will encourage business to invest in plants and equipment to help drive productivity. These are all a step in the right direction for making New Zealand’s manufacturing […]

SouthMACH 2025 hailed as most successful event to date

From June 2025 issue of NZ Manufacturer magazine www.nzmanufacturer.co.nz SouthMACH 2025 has concluded with resounding success, marking the most impactful event since XPO acquired the brand in 2015. This year’s exhibition saw a record number of exhibitors and an impressive 22% increase in visitor attendance, highlighting the burgeoning strength of […]

Christchurch manufacturing trade fair to create opportunities

NZ Manufacturer, a Media Partner for SouthMACH 2025, extends best wishes to exhibitors at the show, commencing today in Christchurch. In challenging economic times we look for the best equipment and services to keep our companies ahead of the game; or at least, breaking even. There is no one simple […]

Investing for growth

The Budget’s Investment Boost is a tax incentive for businesses to invest in productive assets such as machinery, tools and equipment. This means business can deduct 20 per cent of a new asset’s value from that year’s taxable income, on top of normal depreciation. Because the cashflow from investment improves, more […]

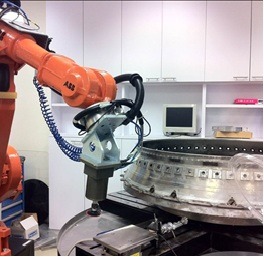

World-class technology and outstanding culture at Architectural Glass Products

Architectural Glass Products (AGP) is a cutting-edge glass manufacturing business based in Hautapu, near Cambridge. Established five years ago, AGP was created to help provide the APL window manufacturer network with a total window solution. It was born from the belief that the local window and glass industry was being underserved, particularly in terms of service and quality. In response, David Bunting, Mitch Plaw, Craig Vincent and Brent Martin joined forces to create a world-class, fully digitalised, and highly automated double-glazing operation. The result is a custom-built, state-of-the-art facility stretching 417 metres long and 108 metres wide, home to some of the most advanced glass processing equipment in the Southern Hemisphere. The Employers and Manufacturers Association’s Nicholas Russell sat down with David to discuss the challenges and successes of launching a greenfield manufacturing operation in New Zealand, the pivotal role of digital transformation, and the importance of investing in people and culture from day one. Why was AGP started?? We felt the glass and window industry in New Zealand was underserved – quality was lacking, and service wasn’t up to par. Our customers, being APL Window Manufacturers, were feeling the pain and we realised the only way to truly improve the supply chain experience was to control it ourselves. That meant starting from scratch and building a manufacturing business that could deliver exceptional products with equally exceptional service. AGP is known for its massive and innovative facility. Can you tell us about the design thinking behind it? We designed the building around the manufacturing process, not the other way around. That gave us complete freedom to optimise product flow and efficiency. The building is 417 metres long (you could park five Boeing 777s inside with room to spare) and 108 metres wide, which helped us futureproof our operations. Aesthetically, it looks […]