Structural adhesives problem solvers

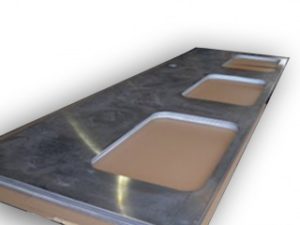

The inherent difficulty with applying a metal skin to a steel frame, whether it be skinning to a vehicle or changing the cladding of a building, is the method of application. The traditional methods have been either pop riveting or welding, both of which leave unsightly heads or distortion from heat.

More and more often manufacturers and architects are turning to structural adhesives for a solution to this problem.

Permabond have a wide variety of adhesives to replace permanent fixing. Their most popular is a two part, non-mixing adhesive that is applied one part to each surface. It will remain inert until the surfaces are brought together giving a handling strength in 2 to 4 minutes and a strength three times that of epoxy. The on part life of the components prior to bringing together can be up to 2 hours.

Another product that has found favour with a number of manufacturers is PermabondÕs single part, heat cured epoxy. This has been used in many instances where heat is an issue, usually with the need to powder coat the finished article. The adhesive is applied to one of the surfaces then lightly clamped in place while baked to cure the adhesive. After the adhesive is cured, the finished product can be powder coated and the joint will easily withstand the temperatures involved in the process.

More traditional two part epoxies are a specialty of Permabond, from the more well-known 5-minute epoxy to adhesives that will withstand 140 ¡C continuously and some that are flexible once cured. The epoxies tend to be packed in 1:1 ratio cartridges for easy application with a dispensing gun and mixer nozzles.

nextSTEP

Tel Homersham Ltd 0800 659 888 or 03 358 8309