Leapfrog Geo enhances flexibility

Leapfrog Geo is a new workflow-based solution for modelling geology and mineralisation. The business benefits for users can often be measured in millions of dollars, making it an essential tool.

Developed in collaboration with industry heavyweights and customers, Leapfrog Geo advances the techniques pioneered in Leapfrog Mining with intuitive workflows that simplify operation and enhance flexibility.

Developed in collaboration with industry heavyweights and customers, Leapfrog Geo advances the techniques pioneered in Leapfrog Mining with intuitive workflows that simplify operation and enhance flexibility.

The focus was on solving key problems with geological modelling that were significantly adding to risk, including not being able to quickly and easily look at different scenarios and hypotheses, and not being able to make the most of the latest information.

A workflow-based solution simplifies model production and make it systemised and auditable. Leapfrog Geo allows geologists and business managers to stand back and see the big picture, better and faster than ever.

Speed, efficiency and flexibility mean opportunities can be capitalised on and risks identified without delay. ROI can also be achieved quicker. Hence limiting their risk exposure and optimising modelling and overall operating efficiency.

Leapfrog Geo’s speed, agility and workflows make light work of building multiple models, which can be tested against multiple futures.

It makes it easy to incorporate new data straight away and change course when needed, which can have a dramatic impact on the bottom line.

Another highlight is the auditable model build process which can be easily verified. A central chronology table sets the geological sequence of model components, and workflows guide the user through the building process.

This approach simplifies and standardises their work, and allows models to be easily updated, reviewed and shared. Decisions become transparent and traceable, further reducing an organisation’s exposure to risk.

Interpolation module

Leapfrog Geo features an add-on Interpolation module that provides a robust indication of the available resource whilst ensuring the effects of geology are incorporated clearly and effectively. Intuitive workflows and simplified operation means rapid grade contouring is now accessible to many levels of users.

Major advance for resource estimation

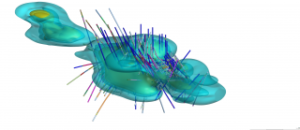

The Leapfrog model is produced as a continuous shape that clarifies artifacts and domaining deficiencies. This rapid grade contouring is not available in traditional geostatistical packages and is an important step in verifying domains and estimating parameters.

The Interpolation module also integrates with, and complements, traditional geostatistical workflows. The successful synergy of implicit geological modelling, interpolation and geostatistics is a major advance for grade shell production.

The power of 3D

A key factor in Leapfrog’s success has been its outstanding 3D graphics. Leapfrog Geo offers even better graphics. High-end OpenGL 3.0 shaders leverage the local graphics hardware and achieve higher frame-rates for even more realistic rendering, especially when using transparencies.

Available in 32 and 64-bit architectures, large data sets can be handled with ease, with a faster engine that powers the software and enables high speed model development.