Remote services for resistance welding

Miyachi now offers remote services for high end resistance welding modules, reducing total cost of ownership thanks to maximised uptime and reduced travel cost.

Available for the Peco ISQ20 series with programming pendant AWS, AWS3 systems, MG3 standard, as well as most customised resistance welding systems, this new business service is ideal for customers with high system uptime demand.

Remote services minimise support efforts and avoid planning and cost for on-site technical support. Specific AWS3 and MG3 products can be upgraded to remote access capabilities.

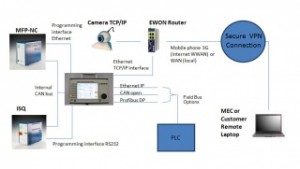

Remote access is achieved with the use of a PC and the installation of a VPN connection that serves as an interface between the Peco product and the remote service expert.

The new business service increases uptime as it allows for fast and efficient diagnostics remotely. It eliminates traveling time to the site and reduces development time by providing remote application support.

The new business service increases uptime as it allows for fast and efficient diagnostics remotely. It eliminates traveling time to the site and reduces development time by providing remote application support.

Customers can also take advantage of core and peripheral system device monitoring, convenient and efficient process adjustments, and availability of continuous process data for long term on-site process statistics.