Delcam to show latest FeatureCAM and new NZ reseller at EMEX 2014

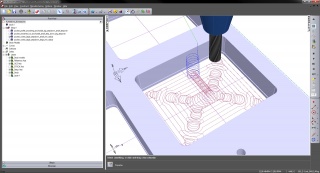

PICTURE: Delcam’s Vortex high-efficiency area-clearance strategy is included in FeatureCAM.

Delcam will demonstrate the latest version of its FeatureCAM feature-based CAM software at the EMEX exhibition to be held in Auckland from 27th to 29th May. The exhibition will also see the introduction of a new reseller for FeatureCAM in New Zealand Ð Auckland-based WorthyCAM.

Recent enhancements to FeatureCAM include the incorporation of the Vortex high-efficiency area-clearance strategy. Vortex gives fast, safe metal removal by allowing solid carbide tooling to cut with its full flute length so minimising machining times.

At the same time, Vortex toolpaths use a controlled engagement angle between the cutter and the part, and so give a more consistent volume-removal rate and feedrate, minimising wear on the cutter.

Other enhancements in the latest release include support for milling and drilling with right-angle heads, one-stop programming of multiple roughing operations, better control of Z-level roughing, and improvements to Wire EDM and chamfering.

Right-angle heads allow internal pockets to be milled and internal holes to be drilled that would be inaccessible, and so impossible to produce, using a conventional head. They are now available as an option on an increasing range of machines, including a wide variety of mill-turn equipment.

Another improvement allows multiple tools, for example, 20 mm, 10 mm and 5 mm end mills, to be selected for roughing and rest-roughing using these strategies, and the complete machining sequence calculated in one operation. A stock model is created automatically after each tool is applied, which is then used as the basis for the program created with the next smaller cutter. This regular updating of the stock model ensures that programs for the later tools are only created in areas where material still remains, so minimising air moves and optimising overall machining efficiency.

Rough machining has also been improved with a new option to set the direction in which Z-level roughing toolpaths are offset. A simple button allows the user to select whether the part should be machined from the outside inwards or from the inside towards the outside. An automatic option can also be chosen where FeatureCAM will decide the offset direction, depending on whether a core or a cavity shape is being machined.

For parts needing wire EDM, the model is often supplied only with a curve showing the shape to be cut rather than a fully-defined feature. FeatureCAM can now project the curve through the stock and also measure the thickness of the feature. The allows the cutting conditions, including feeds, speeds and power levels, to be set at the most suitable values for the EDM equipment.

The cutter compensation used by FeatureCAM can now be specified on an operation level so removing the need to create duplicate features in order to set different values. The most common case where this will be needed is when different cutter compensation is required for the finish pass and for any subsequent chamfering operation.