Smart standard drives provide servo dynamics and precision

Teamed with advanced inverter electronics for smart control functionality, standard asynchronous motors providing IE2 or IE3 efficiency and permanent-magnet IE4 synchronous motors can deliver servo-level dynamics and agility.

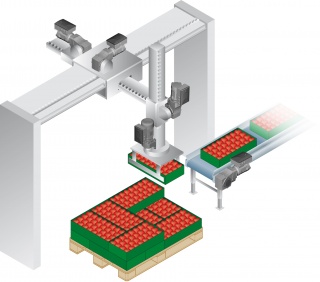

Based on state-of-the-art frequency inverters for motor-mounting, wall-mounting, or cabinet installation, Nord Drive Systems implement highly precise positioning tasks, safety applications, and sophisticated functions such as synchronisation, coordinated multi-axis operation, winding control, and flying shear.

These systems are significantly more economic than conventional servo technology solutions since the purchase costs are much lower and since there is a much larger variety of available system components, including a very versatile gear program that allows for a wide range of custom-specific configurations.

These systems are significantly more economic than conventional servo technology solutions since the purchase costs are much lower and since there is a much larger variety of available system components, including a very versatile gear program that allows for a wide range of custom-specific configurations.

The frequency inverters feature a real-time microprocessor (cycle time 10 ms) and support free programming of drive-related functions according to IEC 61131 to relieve the workload of external PLCs. 200% overload reserve capacity ensures high operating safety, for instance in crane and hoist systems.

Employing field-oriented control technology, these controllers achieve excellent consistency under flexible loads and from near standstill up to the motor´s rated speed, even without an encoder.

Furthermore, the drives provide high starting torques and speed feedback can also be implemented. The top-of-the-range frequency inverter SK 540E from the control cabinet line integrates a universal encoder interface for SSI, BISS, EnDat profile 2.1, and Hiperface.

Nord´s line-up of distributed inverter technology covers the performance range up to 22 kW, while cabinet devices range up to 160 kW. The German drive expert provides full-scale mechatronic drives, manufacturing geared motors and electronics units and programming logic functions in-house.