Rocket Lab to use Siemens software to explore new frontiers of space

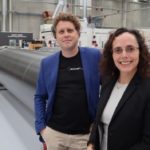

Peter Beck, Rocket Lab CEO, and Samantha Murray, Managing Director of Siemens Digital Industries Software in Australia

Peter Beck, Rocket Lab CEO, and Samantha Murray, Managing Director of Siemens Digital Industries Software in Australia

Rocket Lab will start using Siemens software to scale up production and continue its growth trajectory. To date, the company has launched 40 satellites to space and is expanding services.

Rocket Lab plans to implement Siemens hi-tech industrial software to help digitally manage the lifecycle needs of the business.

The software is from the Xcelerator portfolio, which is from Siemens Digital Industries Software and includes Teamcenter digital lifecycle management software, and NX software for computer-aided design (CAD) and manufacturing.

This announcement comes as Rocket Lab prepares to integrate all its design, engineering and production systems to establish an end-to-end digital thread that enables increased transparency and efficiency across various offices.

Speaking on the decision, Rocket Lab’s Vice President of Global Operations, Shaun O’Donnell, said: “As we’ve grown, so has our production capacity and the platforms associated with various products and processes. Using Teamcenter, we’ll be able to combine various aspects of data related to the same part, assembly and system to maintain a single source of truth across the life cycle of the product. Also, as we grow, NX will give our designers increased performance and stability to cope with larger assemblies.”

“Investing in the right digital platforms that allow us to easily scale with growth is critical to the sustainability of our business. With offices around the world, we rely heavily on the access of relevant information that impacts the efficiencies of our production processes,” said Mr. O’Donnell.

Rocket Lab will use the same software that the top 20 global aerospace manufacturing companies have implemented to drive digital transformation across all phases of operations.

With Xcelerator, Siemens offers the most complete digitalisation value chain to aerospace manufacturers – from the initial concept through to performance in the field –enabling innovation and next-generation design and manufacturing.

Speaking on the announcement, Samantha Murray, Managing Director of Siemens Digital Industries Software in the region, said: “The space race is becoming increasingly important globally and here in Australia and New Zealand. While the real race will be played out way above us, here the pillars driving competitiveness will be digital and dependent on how technologies support access to global supply chains.”

Rocket Lab will use Siemens solutions across the product life cycle including for CAD Management, BOM and configuration management, Engineering Change and Document Management.

Siemens Xcelerator software portfolio is an integrated portfolio of software, services and application development platform that can be personalized and adapted to fit customer and industry-specific needs to help companies of all sizes become digital enterprises. It is widely used to develop some of the most sophisticated global products and systems in industries including automotive, aerospace, shipbuilding and high-tech electronics.