NZ start-up FabriBotics poised to revolutionise metal manufacturing

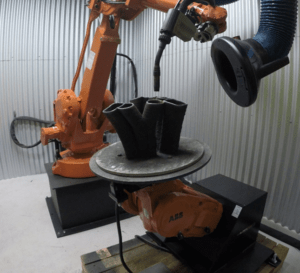

FabriBotics, a new manufacturing start-up based in Tauranga, New Zealand, has developed technology in large-scale metal additive manufacturing. The company’s proprietary technology allows for the production of custom metal parts ranging from 1kg to 1000kg in size, using a variety of weldable materials, including stainless steel, aluminium, steel, and bronze.

Founders Mike Fry and Ben Jackson began working on the 3D printing (Wire-Arc Additive Manufacturing, or WAAM) technology during an MBIE-funded research program at TiDA Ltd. The start-up has secured pre-seed investment from KiwiNet to further develop the technology and business.

The applications for FabriBotics’ technology are vast with the ability to produce custom, large metal parts applicable across many industries, with 1kg to 1 tonne being the target size. Industries include heavy industry, power generation, marine, mining, agriculture, food processing, transport, and architecture. The technology offers a cost-effective solution for creating complex shapes and reducing the costs of machining.

The applications for FabriBotics’ technology are vast with the ability to produce custom, large metal parts applicable across many industries, with 1kg to 1 tonne being the target size. Industries include heavy industry, power generation, marine, mining, agriculture, food processing, transport, and architecture. The technology offers a cost-effective solution for creating complex shapes and reducing the costs of machining.

Using additive manufacturing to produce near-net-shape billets, the technology minimises material waste and maximises the efficiency of the manufacturing process.

The technology also eliminates the need for expensive tooling required for traditional casting methods, making it an attractive option for replacing one-off cast components.

Furthermore, the technology enables extensive repair options for broken metal products, offering a sustainable and economical alternative to replacing entire components.

New Zealand is ideally placed to benefit from FabriBotics’ technology due to its long supply and logistics chains, high cost of labour and low value of metal waste.

The ability to produce custom and niche metal parts on-shore will provide a much-needed solution for industries that currently have limited options for prototyping, spare parts and repairs.

Commenting on the launch of FabriBotics, newly appointed Commercialisation Director Iain Hosie says “The potential for FabriBotics’ technology to revolutionise metal manufacturing in New Zealand is immense. With the ability to produce custom metal parts on-shore, this technology could provide a much-needed solution for industries that currently rely on overseas suppliers. This is an exciting time for manufacturing in New Zealand, and FabriBotics is leading the charge.”

With the potential to transform the way custom metal parts are produced, this start-up is poised to make a significant impact in the industry. For more information, visit their website at www.FabriBotics.nz or see them at Booth #184 at SouthMACH.