Carbon emissions on the way down

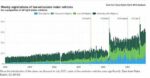

Robert McLachlan, Professor in Applied Mathematics, Massey University. Ian Mason, Adjunct Senior Fellow in Renewable Energy Systems Engineering, University of Canterbury. It may have been largely overlooked in the election debates, but New Zealand’s greenhouse gas emissions are finally on the way down. Annual emissions of carbon dioxide from the burning of fossil fuels are the lowest since 1999 and the 12-month renewable share of electricity is back above 90% for the first time since 1981. The Ministry for the Environment has advised New Zealand is on track to meet the first (2022-2025) carbon budget. All this can be attributed to a range of factors, including fossil gas running low, full hydro lakes, high petrol prices and working from home. But climate policies such as the Emissions Trading Scheme (NZ ETS), the clean car discount and the Climate Emergency Response Fund (CERF) have made a significant contribution to the turnaround. Current decarbonisation policies have and will continue to deliver real emissions cuts, provided they remain in place. It is therefore disconcerting that the National Party plans to take $2.3 billion from the CERF (almost two-thirds of the fund’s mid-2022 balance) to pay for tax cuts. The argument that individual households will use tax cuts to make their own decarbonisation decisions is unsupported by evidence and lacks credibility. The Labour Party has also dipped into this fund, taking $236 million to pay for rebates for household installations of solar panels and batteries, and community energy schemes. These may produce some as yet unquantified emissions cuts. Government funding is working Allocations from the Government Investment in Decarbonising Industry (GIDI) fund to NZ Steel and Fonterra show direct and measurable avoidance of emissions. The installation of an electric furnace at NZ Steel to utilise scrap will save 1% (800,000 tonnes of CO₂-equivalent emissions, or tCO₂e) of New Zealand’s 2021 gross emissions. Support for Fonterra […]