Lean times call for thinner sheets, thicker bends

With the price of sheetmetal arguably at an all time high due to massive demand by Asia and the Middle East, itÕs not just clever software-driven machines that positively impact profit margins.

With the price of sheetmetal arguably at an all time high due to massive demand by Asia and the Middle East, itÕs not just clever software-driven machines that positively impact profit margins.

The simple act of reducing raw material costs has become the latest challenge for fabricators in Australia and New Zealand.

And price reduction doesnÕt have to rely on any hard bargaining Ð tooling technology is getting better and smarter and can now provide an edge.

By a year or two, Europe has encountered many of the challenges our sheetmetal manufacturers are about to face. One particular example from this continent is perhaps a lesson for our companies which may help them avoid any costly trial and error processes to reach a solution.

This European company produces electrical enclosures and cable management systems using a typical turret punching/forming machine.

It wanted to use the minimum material thickness in order to reduce the cost of the component. However, this item is part of a walkway used in a cable management system, so the component needed to be strong enough to be walked on, without deformation.

So basically, the company needed to combine light weight material with structural strength and presented the applications specialists at MATE Tooling Ð represented in Australia and New Zealand by Maxitec – with this very common, yet always challenging task of combining structural strength with minimum material thickness.

The solution was to implement a non-spring loaded custom beaded emboss using the MATE tooling. A beaded embossing or bend is a common way to add strength to a sheet metal part. As the material is deformed, the effective material thickness increases to make it more stiff.

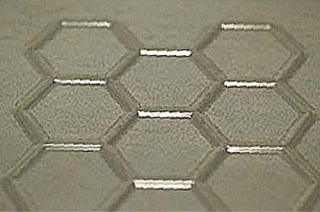

One of the strongest natural shapes is a hexagon. This hexagonal solution using MATE tooling combines the natural strength of a hexagon with the functionality of beading tool into a non-spring loaded custom beaded emboss tool.

The size of the hexagon shape is 1.968(50.00) across the flats. This size exceeds the design parameters for some brands of size-2 spring loaded tools, but the shallow height of 0.040(1.00), and the gentle angle of 60 degrees made this situation an ideal application for a non-spring loaded tool.

The upper assembly is a two piece construction that includes the upper inverted die and a combined shank and alignment ring. The lower tool is a simple die with the profile of the emboss machined on the surface. As the sheet moves, it is stripped from the form on the lower tool.

One of the challenges with this type tool is to ensure that subsequent cycles of the tool do not crush previous forms. Knowing that these forms would be used close together, MATE included a relief at the corner of each form.

This relief prevents the previous form being crushed. The resultant form is strong, aesthetically pleasing, and provides good traction which is essential for this application.

This application was successful because the customer and the tool supplier (in this case, MATE) participated in the design process by sharing all of the relevant information including:

Material Type and Thickness Ð required to assure the correct geometry.

Machine model Ð essential to ensure correct set-up instructions.

Spacing Ð by showing the close spacing of the forms, MATE was able to include the appropriate relief within the upper tool.

Including this information with every request for a forming tool will ensure swift and accurate process.