Delcam on show at SolidWorks World

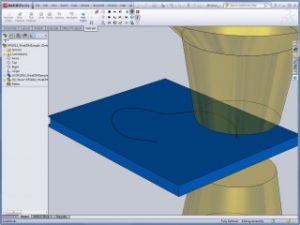

Delcam demonstrated the 2012 version of Delcam for SolidWorks, its integrated CAM system for SolidWorks, at SolidWorks World in San Diego this month.

This latest release includes programming of wire EDM for the first time, alongside the comprehensive options for the programming of turning, mill-turn, drilling and two- through five-axis milling.

Other enhancements include target-part comparison, the ability to compare a model of the desired final shape with the shape achieved by the programmed toolpaths, and multiple-instance programming, the programming of multiple SolidWorks components in one operation, either in the same orientation or in different orientations.

Fully-automated de-burring and chamfering has also been added to give faster programming of these finishing operations on 2- or 2.5-axis parts. The ability to incorporate chamfers, even when they are not shown in the original SolidWorks model, duplicates functionality previously available in Delcam’s feature-based CAM system, FeatureCAM.

Delcam for SolidWorks 2012 also incorporates enhancements from the 2012 release of FeatureCAM, including improvements in the use of stock models and new options in the tooling database.

Stock models allow the user to visualise the material remaining after each operation. This makes it easier to eliminate air cutting and so generate more efficient toolpaths with reduced machining times. The models also simplify the selection of the most appropriate tool sizes for rest-roughing and finishing operations.

The tooling database is a key part of the automation in Delcam for SolidWorks as it allows the optimum operating conditions to be associated with each tool. In most companies, the database is developed by the most experienced user. It then ensures that even inexperienced operators use safe and efficient cutting parameters.

Delcam for SolidWorks, which has been awarded Certified Gold Product status by Dassault Systmes SolidWorks Corp, combines the benefits associated with DelcamÕs PowerMILL and FeatureCAM CAM systems.

It is based on Delcam’s proven machining algorithms that are already used by more than 35,000 customers around the world. The software offers PowerMILL’s exceptional speed of toolpath calculation, plus the advanced strategies for high-speed and five-axis machining, to ensure increased productivity, maximum tool life and immaculate surface finish, even when cutting the hardest, most challenging materials.

At the same time, Delcam for SolidWorks has the same strong focus on ease of use as FeatureCAM, including all of the knowledge-based automation that makes that system so consistent and reliable.

Delcam for SolidWorks is fully integrated into the SolidWorks environment so that the program looks and behaves like SolidWorks. It offers full associativity so that any changes in the CAD model are reflected automatically in the toolpaths. However, this associativity is more intelligent than that offered in many other integrated CAM systems.

Delcam for SolidWorks doesn’t simply modify the existing toolpaths but also reviews the choice of cutting tools and machining strategies, and changes them if necessary.