SOLIDWORKS 2017 is here

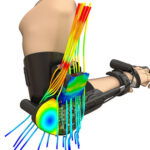

SOLIDWORKS 2017 is the 24th annual release of CAD (MCAD, ECAD), simulation, data management and collaboration tools that delivers the power users need to drive innovation. In this release, 90 percent of the enhancements are driven by user feedback. This year, there are more than 250 new features and enhancements in CAD alone with a total of 520 new enhancements spread across all products. Beyond improving day-to-day productivity, approximately 20 percent of those involve new innovations. There are many core CAD enhancements such as variable Chamfer, super features that convert Chamfer to a Fillet for flexible modelling, advanced hole, enhancements to import mesh files, wrap feature, offset surface, better placement of components while mating that can deliver up to 5X in performance improvements over SOLIDWORKS 2016. Magnetic mates with speedpack enhancements makes it fast and easy to manage large modular assemblies. Like CAD, there are many innovations in simulation with advanced nonlinear (arc length control), better visualisation of hot spots, etc. There are over 100 enhancements in SOLIDWORKS Electrical alone. Extending the ECAD ecosystem, there is SOLIDWORKS PCB powered by Altium, and SOLIDWORKS 2017 is the first full major release for SOLIDWORKS PCB. Customers can now design a full system from PCB boards to electrical wiring, to mechanical and simulation of its connected device in a single environment. The best-in-class collaboration between mechanical, electrical and PCB engineers allows SOLIDWORKs customers to decrease development costs, significantly improve time to market and reduce the number of prototypes and errors. New in SOLIDWORKS 2017 is Term Licensing in additional to perpetual licensing model. This allows SOLIDWORKS customers to scale on demand, purchase from OPEX budget and entrepreneurs and startups to design in SOLIDWORKS while getting a Term License. Customers will have full flexibility – they can purchase SOLIDWORKS as Perpetual or a quarterly/annual Term […]